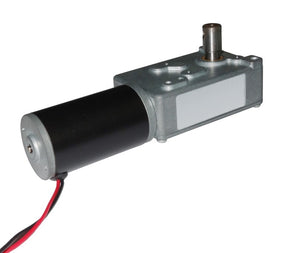

A rotary actuator, also known as a DC gear motor, is the dynamic counterpart of a electric linear actuator. Unlike their linear counterparts, rotary actuators specialize in rotational motion, providing essential turning force to move various components within machines and systems.

Imagine them as the spinning heart of a machine, enabling fluid movements in industrial machinery, valves, robotics, and even windscreen wiper motors. Thanks to their versatility, rotary actuators come in an extensive range of sizes, catering to diverse applications.

At the core of a DC Gear Motor is the electric gear motor, responsible for transforming linear motion into a usable rotary motion. By utilizing gears, the motor's speed is reduced while torque is increased, ensuring practical and controlled rotary movement for everyday applications.

Rotary actuators are designed to withstand tough conditions and are well-suited for outdoor and harsh environment applications. Many rotary actuators come with robust sealing and protection against dust, water, and other contaminants, ensuring reliable performance even in challenging conditions.

These DC gear motors are often constructed using durable materials like stainless steel or corrosion-resistant coatings, making them resistant to rust and environmental damage. Additionally, some models are rated with an IP (Ingress Protection) rating, which indicates their level of protection against solid particles and liquids. For example, an IP67-rated actuator is dust-tight and can withstand temporary immersion in water up to 1 meter deep.

Whether it's in construction, marine, agriculture, aerospace, or any other industry, rotary actuators prove to be reliable workhorses, providing precise movement control even in the harshest outdoor environments. Before selecting an actuator, it's essential to check its specific IP rating and suitability to ensure it meets the demands of your application.

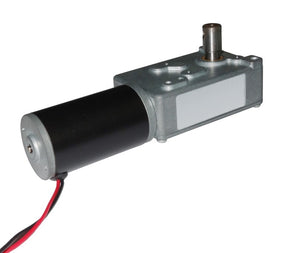

A DC gear motor is another name for a rotary actuator. A DC gear motor is a type of electric motor equipped with a gear mechanism. It combines the power of a DC (Direct Current) motor with a gear actuation system to deliver controlled and efficient rotary motion. The gear arrangement within the motor slows down the motor's rotational speed while increasing the torque output, making it ideal for applications that require precise and powerful rotations.

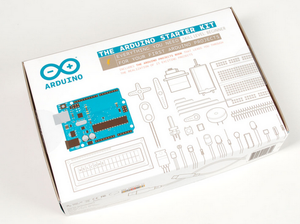

DC gear motors are widely used in various industries and applications, such as robotics, automation, automotive, and home appliances. Their versatility, reliability, and ability to provide the necessary torque make them a popular choice for rotarymotion control solutions.

At Firgelliauto, we offer a diverse range of high-quality DC gear motors, each tailored to meet specific requirements. Whether you need a compact motor for a small-scale project or a robust motor for heavy-duty applications, our selection has you covered. Trust in the efficiency and performance of our DC gear motors to elevate your automation projects to new heights.

While both DC motors and DC gear motors share similarities as electric motors powered by direct current, they differ in their design and functionality.

Basic Functionality:

-

DC Motor: A DC motor converts electrical energy into mechanical motion. It spins at a constant speed determined by the input voltage.

-

DC Gear Motor: A DC gear motor combines a DC motor with a gear system. The gear mechanism reduces the motor's rotational speed while increasing the torque output, providing controlled and powerful rotations.

Speed and Torque:

-

DC Motor: A standard DC motor has a fixed speed determined by the applied voltage. It can achieve high speeds but may lack the necessary torque for certain applications.

-

DC Gear Motor: The gear system in a DC gear motor enables variable speed control and offers increased torque, making it suitable for applications requiring precise and powerful rotary motion.

Applications:

-

DC Motor: DC motors are commonly used in applications where constant speed and lower torque are sufficient, such as fans, blowers, and small devices.

-

DC Gear Motor: DC gear motors are ideal for applications demanding controlled and slow rotations with higher torque, including robotics, automation, conveyor systems, and automotive mechanisms.

Efficiency:

-

DC Motor: DC motors are generally more efficient in converting electrical energy into mechanical energy due to their simple design.

-

DC Gear Motor: Although the gear actuation system introduces some energy losses, DC gear motors are still highly efficient, especially when optimized for specific tasks.

Size and Weight:

-

DC Motor: Standard DC motors are compact and lightweight, suitable for applications with limited space.

-

DC Gear Motor: DC gear motors are typically slightly larger and heavier due to the addition of the gear mechanism, but they offer superior torque capabilities.

DC gear motors play a crucial role in a variety of industries, offering precise and controlled motion for numerous applications. Here are six key areas where DC gear motors find extensive use:

Automation and Robotics-

DC gear motors are integral to the movement of robotic arms and automation systems. They enable robots to perform tasks with precision, such as assembly, packaging, and material handling. These motors ensure smooth and accurate rotational motion in various industries, from manufacturing to logistics.

Automotive Systems-

In the automotive sector, DC gear motors are employed in functions like power window control, seat adjustments, and windshield wiper movement. Their compact size and ability to deliver specific levels of torque make them essential for enhancing comfort and convenience within vehicles.

Medical Devices-

DC gear motors contribute to medical instruments and devices, ensuring controlled motion in equipment like infusion pumps, diagnostic devices, and robotic surgical tools. Their reliability is critical in maintaining accuracy and safety in healthcare applications.

Home Appliances-

From kitchen appliances to personal care devices, DC gear motors enable various functionalities. They power mechanisms in blenders, coffee grinders, electric toothbrushes, and other household items, ensuring consistent performance and user convenience.

Industrial Machinery-

Industries such as manufacturing and material handling rely on DC gear motors for controlled motion in conveyor systems, assembly lines, and packaging machinery. Their ability to deliver precise movement enhances production efficiency and product quality.

Aerospace and Defense-

DC gear motors are used in aerospace applications to control components like flaps, valves, and mechanical actuators. In defense, they find use in missile guidance systems, surveillance equipment, and unmanned aerial vehicles (UAVs), ensuring reliable and accurate rotary motion control in critical scenarios.

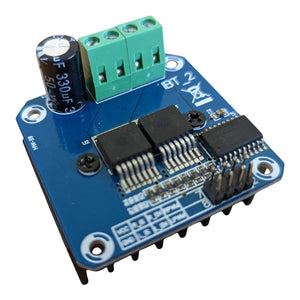

Selecting the right gear motor involves a strategic process centered around torque requirements and output speed. Here's a step-by-step breakdown to guide you:

Assess Torque Requirements-

Begin by understanding the force or load your application demands. Calculate the torque needed to overcome resistance, ensuring the motor can handle the workload. Factoring in aspects like initial load, friction, and incline variations gives you a clear picture of the torque range necessary for optimal performance.

Define Desired Output Speed-

Determine the motion speed that suits your application. Whether it's a slow and controlled movement or a faster action, identifying the ideal output speed helps in selecting the appropriate gear ratio. Consider the trade-off between speed and torque, as higher gear ratios offer reduced speed but increased torque.

Understand Duty Cycle for Consistency-

Gauge how frequently the motor will be operational in your application. Is it continuous, intermittent, or sporadic? Matching the motor's duty cycle with your usage pattern ensures reliability and prevents overheating. This step prevents premature wear and tear, enhancing the motor's lifespan.

Account for Space Constraints-

The physical dimensions of the gear motor are crucial. Measure the available space for mounting and integration. A compact motor that seamlessly fits within your setup guarantees efficient usage without compromising on performance. Prioritize form factor while ensuring it aligns with your torque and speed needs.

Review Technical Specifications Thoroughly-

Delve into the manufacturer's technical data to confirm compatibility. Study torque-speed curves, power ratings, load capacities, and gear ratio options. Paying attention to these details guarantees that the chosen gear motor aligns harmoniously with your application's torque and output speed requirements.