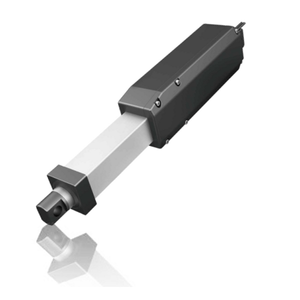

A Micro Linear Actuator, which is a small actuator, is a device that requires an energy source input and an external signal input. These inputs create an output usually in the form of motion that can be either rotary or linear. An Electric Linear Actuator is a device that converts the rotational motion of an AC or DC motor into linear motion. It can provide both push and pull movements. This movement makes it possible to lift, drop, slide, adjust, tilt, push, or pull objects with the simple push of a button. Today there are hundreds of millions of Actuators used in the world to perform many different tasks. An Electric Micro Linear Actuator consists of a DC or AC motor, a series of gears, and a lead screw with a driving nut that pushes the main rod shaft in and out. FIRGELLI sells 12v Linear Actuators and 24v Linear Actuators.

There are many factors which you need to take into account when choosing which micro linear actuator you need for your project. Mainly the Stroke and Force. If you know the stroke and force that you need, then you can use our Actuator Calculator to work out which micro actuator is best. Other factors could include how much space you have available for the retracted actuator to take up, as well as the speed of the micro actuator. Compare our micro actuator's dimensions to what you need to see which fits the best. If you are unsure our team at Firgelli is happy to help, give us a call.

Now that you have decided which micro actuator you will use, you will need to consider how you will control your actuator. At Firgelli we have many different Switches, Remotes, and Arduino which can all be used depending on your preference. Head over to our Actuator Controls page to find the right control option for you.

The first thing to know is that a micro linear actuator does exactly what its name implies: it actuates (or 'moves') in a linear (or 'straight') fashion. There are many different ways that a motor can do this, and their motion is commonly achieved with a rod extending and retracting, or a slider that moves on a track. The linear motion is created by using a Lead-screw. The screw turns either clockwise or counter-clockwise and this causes the shaft, which is basically a nut on the screw to move up and down the screw as the screw turns. This is what converts rotary motion from the electric motor to Linear motion.

The motors used are either AC or DC motors, most however run on 12v dc. To make a Linear Actuator go the opposite direction you simple reverse the wires from the Actuator (reverse polarity) from the battery or power supply. This is typically done through a switch that automatically reverses the polarity to the motor for you. Different speeds and forces are achieved by using different gear ratio's inside the Linear Actuator gearbox system. Please remember in our micro actuators, or rather all Linear Actuators, force and speed trade off against each other. That means if you want high force you have to settle for a lower speed than if you require lower force. This is because the only constant in a Linear Actuator is the Motor speed and force for a given input voltage.

To make the shaft stop when it gets to the end of the stroke, our products have built-in limit switches or micro switches as they are sometimes known. These limit switches are inside the main shaft and are nothing more than a small switch that is triggered by the nut inside that slides up and down the screw. There is one for the top extended position and one for the lower retracted position. For more information on this, check out our Blogs page.

Yes, you can save on your order when purchasing our Actuators in large volumes. Discounts will be calculated at checkout. Our base discount is 20% when you purchase a minimum quantity of 11 units of an actuator, and then the discount scales up as you purchase more. The full discount information table can be found on each actuator product page.