Harness Precision with our Feedback Actuators

Introducing our latest collection of actuators featuring Optical Sensors for unparalleled feedback accuracy. The OS Series is designed to revolutionize your automation needs with seamless positioning control. Engineered with built-in optical sensors, these feedback linear actuators deliver real-time feedback, ensuring precise positioning every time. With three force options ranging from 35 to 400 lbs, built-in limit switches, and high-grade aluminum construction, these actuators are built to exceed your expectations. Explore the benefits and drawbacks of different feedback options and elevate your control system with the Synchronous Control Board for synchronized movement across multiple actuators.

- Force 500–1124 lb's

- Stroke 6–40 Inches

- Force 900–1500 lb's

- Stroke 6–40 Inches

Top Blog Posts for Feedback Actuators

Actuators are the unsung heroes behind countless devices. From automotive systems to home appliances, they're ubiquitous in today's world. But what exactly are actuators, and...

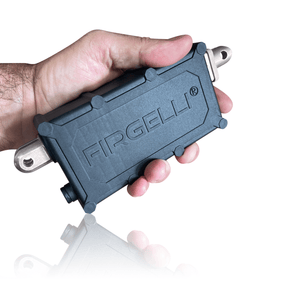

Unlock the power of precision in automation. Synchronize multiple electric linear actuators using Firgelli Automation's advanced control board. From wiring to configuration, learn how to...

Explore the essentials of feedback actuators, including potentiometer, Hall sensor, and optical sensor technologies. Learn the pros and cons of each type to determine the...

The approach for mounting a linear actuator involves the utilization of clevis end mounting brackets. In this widely adopted mounting technique, the brackets are affixed...

Learn how an arduino, a open-source electronics platform, offers unparalleled control and automation for feedback actuators, in various DIY projects and installations. Discover the simplicity...