Utilizing feedback to ensure precise movements is key in any automation project from robotic to TV lifts. Proper implementation of feedback allows for accurate closed loop control of your linear actuator; no longer do you need to manually check that your linear actuator goes to the right position. As linear actuators are typically used to move an object from one position to another, the most important feedback to receive from your actuator is its position. Linear actuators that have positional feedback will typically measure position using one of the 3 different sensors; potentiometers, hall effect sensors, and optical sensors.

Potentiometers

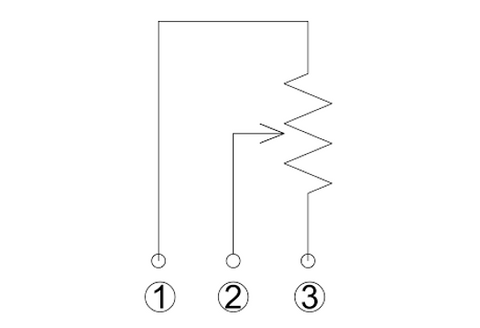

Potentiometers are variable resistors that when used in linear actuators, their resistance changes based on the position of the actuator. Potentiometers will consist of the 3 pins as shown below, pin 1 is the input voltage, pin 3 is ground, and pin 2 is the adjustable resistor. You can read the output of the potentiometers by measuring the voltage between pin 2 and ground, which will change as the actuator moves. To effectively implement this feedback, you’ll need to make use of some type of controller, like an Arduino, to read this positional value as the actuator moves.

One of the biggest strengths of a potentiometer is that it provides an indication of absolute position of the linear actuator. Because of this, this feedback can be quite easy to handle in the software of a controller as you can simply compare the current output reading to the output reading of your desired position. You’ll also never have to worry about losing your actuator’s position if you turn off your system as the resistance of the potentiometer will be the same regardless of being powered or not.

There are few drawbacks of using potentiometers for positional feedback. One drawback is that the feedback from the potentiometer can be affected by electrical noise and may require you to filter the signal to achieve stable results. The output of the potentiometer is also dependent on the input voltage to the potentiometer, which may make it difficult to ensure multiple linear actuators are moving simultaneously as the output signal may vary slightly due to slight changes to the input voltage. Also, potentiometers generally won’t be as sensitive to smaller movements of the linear actuator, compared to the other feedback options, making repeatable results more difficult.

Hall Effect Sensor

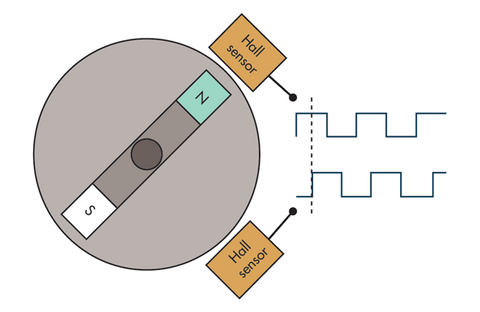

Hall effect sensors work based on the hall effect which is the effect of a magnetic field to produce a voltage. Hall effect sensors can either provide a digital or linear output, but for linear actuators, they typically use digital output hall effect sensors. When these sensors detect a magnetic field, they will produce a voltage that can be read by a controller [1]. With linear actuators, these sensors are positioned inside the gearbox of the actuator along with a magnetic disc. As the linear actuator moves, this magnetic disc rotates pass the hall effect sensor which produce a pulse of voltage. These pulses can be used to determine how far the actuator has moved. Generally, linear actuators that use hall effect sensors to provide positional feedback will specify the pulse per inch traveled which you can use to determine how far the actuator moves. For example, if you detected 6000 pulses and your actuator has a pulse per inch traveled of 12000 that means your actuator has moved 0.5 inches.

The major downside of using a hall effect sensor for positional feedback compared to a potentiometer is that hall effect sensors do not measure an absolute position. Instead they produce pulses that can be counted to determine how far the actuator has moved, which requires you to know where the actuator starts to determine the absolute position. This can be overcome in software of your controller, like in an Arduino, by storing the current position of the actuator and always starting the actuator from a known position, like fully retracted. This may require you to home the actuator to this known position every time you turn on your system.

The strength of using a hall effect sensor for positional feedback is that it provides much greater resolution compared to the feedback from a potentiometer. As there can be 1000s of pulses per inch of movement, hall effect sensors provide a precision and reliability in positioning your linear actuator. The pulses will also vary in frequency based on the speed of your linear actuator which means you can use them to measure the speed of your linear actuator. Hall effect sensors also provide greater ability to ensure multiple linear actuators move together simultaneously as the pulse counts are more accurate than the changing voltage of the potentiometer. Utilizing our FA-SYNC-X actuator controller, you can even ensure the actuators move in unison irrespective of load.

Optical Sensor

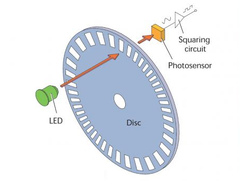

Optical Sensors that are used in linear actuators (there are other type of optical sensors) function very similar to hall effect sensors except they detect light using a photodetector [2]. Optical sensors work by having light from a LED or some other light source be passed through an encoder disk. This encoder disk is slotted to allow the light to pass through it periodically. On the other side of the disk is the photodetector, which detects the light when it passes through the slots in the disk and creates an output signal [3]. As the actuator moves, the encoder disk rotates and light is detected by the photodetector which produces a pulse of voltage. These pulses can be used similarly to the pulses of a hall effect sensor to determine how far the actuator has moved. Linear actuators that use optical sensors for positional feedback will also specify the pulse per inch traveled which you can use to determine how far the actuator moves.

Optical Sensors, again, have similar strengths and drawbacks to hall effect sensors when compared to potentiometers. They have greater accuracy and resolution, even greater than hall effect sensors, and can be used to measure the speed of the linear actuator. They are also better at ensuring your multiple linear actuators move simultaneously and can make use of the FA-SYNC-X actuator controller. They also do not measure absolute position and instead require you to count pulse to determine how far your actuator has moved. You’ll also need to start in a known position as you’ll need to save the current position in software to keep track of the absolute position.

Summary

Your choice of type of feedback you want from your linear actuator will depend on what you feel is more important for your application. Do you need a high level of accuracy? Choose a linear actuator with optical or hall effect sensor. Do you not want to have to set your actuator to a home position every time you turn it on? Then go with a linear actuator with a potentiometer. Do you want to control multiple linear actuators simultaneously? Choose a linear actuator with optical or hall effect sensor. Do you want your feedback to provide an absolute position? Go with a linear actuator with a potentiometer.

[1] Monari, G. (June, 2013) Understanding Resolution In Optical And Magnetic Encoders. Retrieved From: https://www.electronicdesign.com/technologies/components/article/21798142/understanding-resolution-in-optical-and-magnetic-encoders

[2] Paschotta, R. Article on Optical Sensors. Retrieved From: https://www.rp-photonics.com/optical_sensors.html