Linear Rails are used when the task requires great precision and very little friction in the movement of an object. This is why they are very popular when manufacturing, distributing, or packing products, and are widely used across all industrial sectors. The only real complexity lies in the different names used for Linear Rails: linear guide rails, linear guides, linear guideways, linear slides, and linear guidance systems.

No matter what you call it, a Linear Rail efficiently moves loads along a determined horizontal or vertical path with a minimum of friction or resistance. Linear Rails are usually made from high-strength, hardened, and galvanized Steel so they resist corrosion.

As a rule, Linear Rails are the most suitable for high loads, also being designed to deliver a very precise linear motion. Rail guides come in every size from miniature Linear Rails designed for moving tiny components in limited spaces right up to mammoth examples for moving components that could weigh more than a tonne.

Linear Bearings slide rails move on a Linear Axis in a straight line. Because they are a bearing it allows you to move a significant amount of weight in a linear motion with great ease. The Linear Bearing takes all the weight without restricting the linear motion of the object, hence the name.

Linear Bearing slide rails provide accurate, stable, and smooth linear guidance under a wide range of speeds, loads, conditions, and space requirements. Linear Bearings are used in applications that require linear motion of heavyweights in a repeatable motion.

We offer different style Linear Bearings to suit most applications, from the mini to the larger heavy-duty Linear Bearing for heavyweights.

In many linear actuator applications, you may need additional supports to help move your desired object or to protect your linear actuator from uneven loads. Generally, you’ll have two choices of supports you have to pick from; Linear Guides and Drawer Slides. But what is the difference? Why choose one over the other and how do you know which one is best for your application?

Linear Sliding Rails

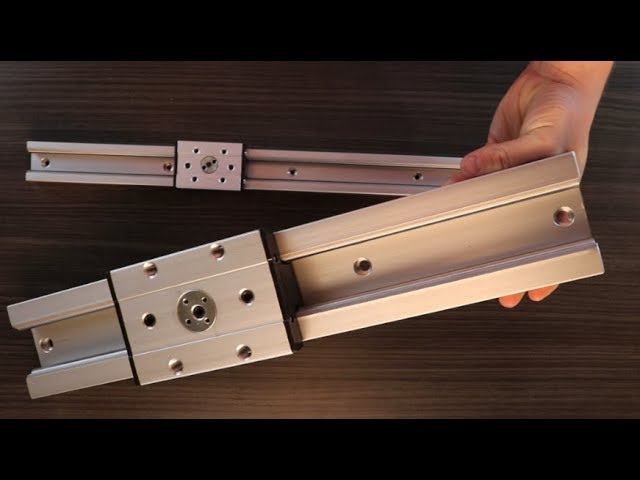

Linear Bearing Slide Rails are support mechanisms that are used to carry heavy loads and ensure straight and level linear motion. Linear guides will usually consist of two components; the sliding carriage and the rail. The sliding carriage is the element that moves along the rail and supports the attached load.

The two most common styles of linear guides are the sliding contact guides and roller bearing guides. Linear guides are designed to allow you to move a significant amount of weight along with a single axis with great ease and their load carrying capability allows linear motion without restriction. If you want to learn more, check out our Linear Bearing 101 blog

Drawer Slides

drawer slide is a mechanism that can carry an object and allows for telescopic motion in one axis. Drawer slides generally work by having one drawer member that slides over a cabinet member, which allows the entire mechanism to extend or retract. Generally, you will use a pair of drawer slides in any application and will most likely encounter two main types: Roller Slides and Ball-Bearing Slides, although ball-bearing drawer slides do provide a larger carry load capacity and longer extensions

If you want to learn more about Drawer Slides, you can check out our drawer Slides 101 blog to learn more. Drawer slides are commonly found in a wide range of household or office applications like desk drawers, kitchen cabinets, and pull-out cutting boards but can be used in a wide range of applications that require linear extension and retraction.

Which one should I choose?

Your choice between whether to use a drawer slide or linear guide is almost completely dependent on your application. The design differences described above make it clear that certain applications are better suited for linear guides, while others are more appropriate for drawer slides.

If your application is similar to a common cabinet application or if you require telescopic motion, then drawer slides may be the best option for your application. If you require support to stabilize an actuating component and protect it from uneven loads and torques, then linear guides are a good option for you. There are also many instances where both linear guides and drawer slides may be used and, in this case, you must prioritize the differences between these supports to decide which one is for you.