Actuator Motors

Introduction

Have you ever wondered what drives the precise movements in industrial machines or even simple home gadgets? It's the actuator motors working quietly behind the scenes. These dynamic components convert electrical signals into smooth, controlled motions. In this deep dive, we'll unravel the intricacies of electric linear and rotary actuators, demystify their workings, and highlight their indispensable role in modern technology. Whether you're curious about their differences, benefits, or how to replace one, we've got it covered. Stay with us and get all your actuator questions answered!

1. What is an Actuator Motor?

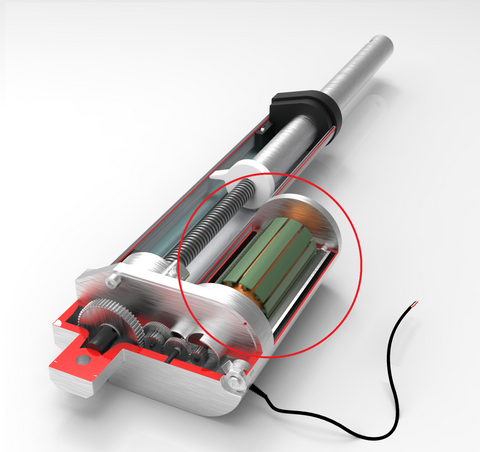

An actuator motor is a component of motion control systems, responsible for moving or controlling a mechanism or system. In simple terms, it's a type of motor that converts electrical energy into motion, allowing for precise control of movement in various applications, from industrial machinery to home automation. In the case of a Linear Actuator motor, the motor represents the input motion that takes electricity to produce usable rotary motion for the Actuator to produce actual work. In other words, its the Motor that provides the work and everything that goes after the Motor is whats converting the rotary motion of the motor into usable motion such as converting it into linear motion, and slowing down the speed and increasing the torque.

2. Types of Actuator Motors

While we will focus on electric linear actuators, it's worth noting the existence of rotary actuators. Both types play significant roles in numerous industries, and the motors used within them can be exactly the same. So a Linear Actuator and a Rotary Actuator, could in fact utilise the same Actuator motor. The motion is simply converted differently to result in different motion at the end.

-

Electric Linear Actuators: These actuators transform electric energy into straight-line motion. You'll commonly find them in machinery, robotics, and even home appliances.

-

Rotary Actuators: As the name suggests, these actuators produce rotational motion. They can be powered by different means, but in this article, we'll highlight the electric version.

3. How Do Electric Linear Actuators Work?

Electric linear actuators consist of a motor, gearbox, and a lead screw. As the motor operates, it turns the lead screw via the gearbox. Depending on the motor's rotation direction, the lead screw will either retract or extend, producing a linear motion.

4. Benefits of Using Electric Linear Actuators

-

Precision: Electric linear actuators offer accurate and repeatable motion, which is crucial in many applications.

-

Simplicity: With fewer parts than other actuation methods, maintenance and setup become easier.

-

Flexibility: These actuators can be adjusted to fit a broad range of force requirements and speeds.

-

Energy Efficiency: Electric actuators typically consume power only when moving, saving energy in the long run.

5. Rotary Actuators: What You Need to Know

Rotary actuators turn around a fixed pivot, providing rotational motion. They have a wide range of applications including valve operations, robotics, and conveyor systems.

-

Mechanism: They primarily consist of a motor, which powers a rotating shaft.

-

Advantages: Rotary actuators offer high torque in compact designs, making them suitable for applications where space is a constraint.

6. How to Replace an Actuator Motor?

Replacing an actuator motor might sound complicated, but with the right tools and steps, it's straightforward. In the case of a FIRGELLI replacement Actuator motor, you will need to open up the actuator and unscrew the old Actuator motor and replace it with the new one, the harder part will be having to deal with the 2 wires that connect the actuator to the motor. All motors have 2 wires to each motor, so some soldering maybe required to replace an actuator motor.

Step-by-step Guide:

-

Safety First: Always disconnect the power supply to ensure safety during the replacement process.

-

Accessing the Actuator: Open up the rear body housing to access the actuator motor, we clal this the fixed end of the actuator.

-

Uninstall the Old Motor: Detach any connectors and unscrew the motor from its mounting. Usually this is 2 long screws that are accessed from the outside of the Actuator motor body, but go all the way through the motor into the main body of the actuator.

-

Install the New Motor: Position the new actuator motor in place, secure it, and reattach any connectors.

-

Testing: Once installed, power up the system to test the new motor's functionality.

7. FAQs about Actuator Motors

-

Q: How long do actuator motors last?

- A: Lifespan depends on factors such as usage frequency, load, and maintenance. However, well-maintained electric linear actuators can last several years. In the case of an actuator motor used in a linear actuator, lifespan is also influenced by the actuator's stroke. This is because the longer the stroke, the more the motor has to rotate to achieve that stroke. For instance, a 1" stroke actuator might last up to 10 times longer than one with a 10" stroke. Additionally, a lower force actuator will generally have a longer lifespan than a higher force one, as the motor doesn't need to rotate as much to produce the same amount of force.

-

Q: Can I use an actuator outdoors?

- A: Yes, but ensure it's rated for outdoor use, considering factors like weather resistance.

-

Q: How do I choose the right actuator motor for my application?

- A: Consider factors like load, speed, stroke length, and your specific application requirements.

In Conclusion:

Actuator motors, particularly electric linear and rotary actuators, are integral to modern machinery and automation. Understanding their function, benefits, and maintenance is vital for anyone in industries that rely on precise movement and control. Remember, always prioritize quality and compatibility when selecting or replacing actuators for optimal performance and longevity.