The short answer is yes, but there are some factors you’ll need to consider. Firstly, pushing forces are associated with the linear actuator extending and pulling forces occur when it is retracting. Not all types of linear actuators will have the same force capacity for pulling compared to pushing. This means the actuator will not be able to pull the same load that it pushes, and this difference will be listed in the specifications of that actuator. This is much more commonly seen in pneumatic and hydraulic linear actuators than in electric linear actuators.

Pneumatic & Hydraulic Linear Actuators

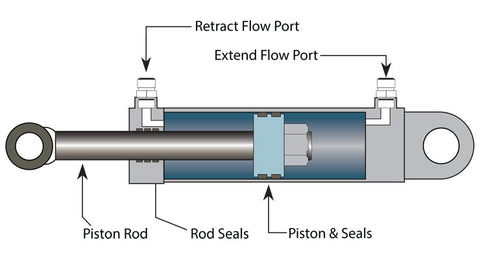

Pneumatic and Hydraulic linear actuators or cylinders generally consist of a hollow cylinder and rod which extends or retracts with increasing pressure on one side of the rod. The pressure increase is caused by high pressure air for pneumatic cylinders and by incompressible liquid for hydraulic cylinders [1]. The image below, from [2], shows a basic hydraulic linear actuator which will be very similar to a basic pneumatic linear actuator. The increase pressure causes a linear force that is equal to the pressure times the cross sectional area of the hollow cylinder. As you can see in the image below, the volume on the retract flow side of the linear actuator is smaller than the extend flow side due to the presents of the rod. This means the resultant force created for the same pressure increase is less when retracting than when extending [2]. There are some different types of pneumatic and hydraulic linear actuators that work slightly differently and might midgait this reduction in pulling force, but it will generally be lower than pushing forces for these types of linear actuators.

Electric Linear Actuators

The basic rod-style electric linear actuator works by having a motor convert electrical energy into mechanical rotation which is then reduced by a gearbox and causes a lead screw to rotate. As the lead screw rotates, a nut moves along the lead screw. Attached to this nut, is the rod that moves outwards as the nut moves up the lead screw and creates a pushing force. The retraction of the rod to create a pulling force is done in a similar fashion except the nut moves back down the lead screw and the mechanical rotation is in the other direction. There are other types of electric linear actuators that work a bit differently but follow a similar method to generate force.

The size of the force generated by an electric linear actuator is dependent of the size of the motor, the gearbox ratio, and the lead screw pitch. As these components can function equally in both clockwise and counter-clockwise rotation, the pulling force will be identical to the pushing force.

Conclusion

If in your application, you require sufficient pulling force from your linear actuator, you will need to consider your choice of type of actuator carefully. You may be required to choose a larger pneumatic or hydraulic linear actuator to provide the necessary pulling force for the same given pushing force. Or you may simply go with an electric linear actuator that will have the same pulling and pushing force. While these different types of actuators have their advantages and disadvantages, if sufficient pulling is required, you’ll need to remember that all actuators don’t pull and push with the same force.

References:

- Gonzalez, C. (April 2015) What’s the Difference between Pneumatic, Hydraulic, Electrical Actuators. Retrieved From: https://www.machinedesign.com/mechanical-motion-systems/linear-motion/article/21832047/whats-the-difference-between-pneumatic-hydraulic-and-electrical-actuators

- Gannon, M. (February 2017) The Business End of Hydraulics: The Cylinder. Retrieved From: https://www.mobilehydraulictips.com/business-end-hydraulics-cylinder/

Title image retrieved from: https://99percentinvisible.org/article/norman-doors-dont-know-whether-push-pull-blame-design/