|

|

| 1. Basics of an actuator |

| 2. Different types |

| 3. Applications |

| 4. How to choose |

| 5. How to install |

| 6. Versatility |

1. Basics of an actuator

An actuator can be described as a component found within various devices and machines, whose function is to convert energy from different sources, such as electrical power, hydraulic pressure, pneumatic forces, and more, into controllable mechanical motion. The specific input requirements and operational characteristics of an actuator depend on the type of energy to be converted and the intended purpose of the actuator.

HOW DO ACTUATORS WORK

Electric actuators utilize electric current or voltage as input to generate the desired mechanical output. Hydraulic actuators leverage incompressible fluids to produce force and motion, while pneumatic actuators rely on compressed air to achieve the same result. Regardless of the specific energy input, the ultimate outcome is the conversion of energy into mechanical energy, which manifests as physical movement or the execution of mechanical tasks.

Despite not gaining the same level of daily media attention as concepts like artificial intelligence and machine learning, actuators occupy a crucial role in the modern world, unparalleled by most other devices ever invented. They serve as indispensable components in numerous industrial applications, ranging from mechatronics systems controlling robotic arms to the precise management of engine parameters in automotive systems. Actuators contribute significantly to the efficient and effective operation of various machinery and equipment and there are billions of them in existence today.

In summary, an actuator represents a vital link between energy sources and mechanical output, converting diverse forms of energy into controlled physical motion. Its reliable and precise functioning enables the practical realization of numerous technological advancements, underscoring its indispensable status in today's industrial landscape.

"Actuators may not grab headlines like artificial intelligence and machine learning do in the media, but they play an integral role in our modern world that is unparalleled by any other device ever created."

2. Different types

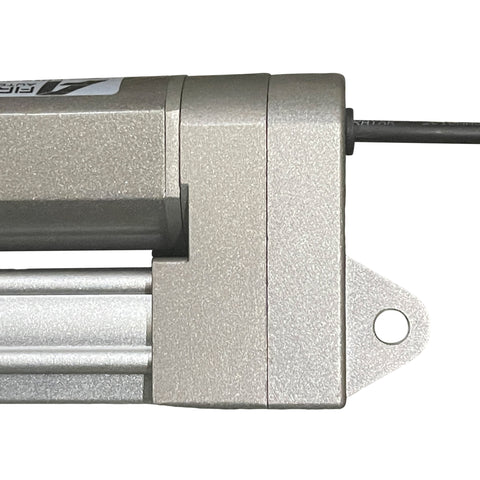

ELECTRIC LINEAR ACTUTORS

First, we have electric linear actuators. Picture these as the workhorses of the actuator family. They're designed to produce linear motion, meaning they push or pull in a straight line. Think of a motorized rod extending or retracting, enabling precise and controlled movement. Electric linear actuators find applications in various domains, from robotics and automation to adjustable furniture or even medical equipment.

ROTARY ACTUATORS

Next, we have rotary actuators, or DC Gear Motors, as they are sometimes called. These are the siblings of electric linear actuators, but instead of linear motion, they rotate or turn. They're like the spinning heart of a machine, providing rotational force to move components. You'll find rotary actuators in things like industrial machinery, valves, robotics, or even windscreen wiper motors, so as you can imagine they come in a huge range of sizes too. DC Gear motors are found in all Linear Actuators, it is not until you add a leadscrew and some electronic limit switching do they turn into a Linear Actuator. The Electric gear motor is what creates the rotary motion from a Motor, and the gears are used to slow down the speed but increase the torque, to allow for a more usable rotary motion to be made available for every day applications. To summarize a DC gear motor, it makes rotary motion usable. An electric motor on its own is not very usable, They are too fast and don’t have much torque. The gear box is added onto the motors to slow them down and increase torque to make a useful motion control device.

PIEZO ACTUATORS

Now, let's talk about piezo actuators. They're the technological magicians of the actuator world, using piezoelectric materials. When an electric field is applied, these materials change shape, resulting in highly precise motion. Piezo actuators are known for their exceptional accuracy, responsiveness, and ability to operate in demanding environments. They're often used in fields like nanotechnology, microscopy, and even in high-end audio devices. The downside of Piezo actuators is that their stroke in in the microns, in fact you are never likely to see a Piezo actuator with a stroke of more than 10mm.

HYDRAULIC AND PNEUMATIC ACTUATORS

Moving on, we encounter hydraulic and pneumatic actuators. They operate on different principles, but both use fluid power to generate motion. Hydraulic actuators use incompressible liquids, while pneumatic actuators employ compressed air. These actuators are known for their immense force capabilities, making them ideal for heavy-duty applications. You'll find hydraulic actuators in construction machinery, industrial presses, or even aircraft landing gear. Pneumatic actuators, on the other hand, are commonly found in automation systems, air-powered tools, and even in the control of valves or gates.

Lastly, we have track actuators also known as slider actuators. They're like the versatile performers of the linear actuator family, capable of linear motion along a track or rail. Imagine a slider moving smoothly back and forth, enabling precise positioning or adjustments. Track actuators find use in various applications such as robotics, camera sliders for filming, or even in medical devices where accurate movement along a track is required.

3. Applications

Actuators play a crucial role in bringing motion and automation to various devices and systems we encounter in our daily lives. These devices act as the "muscles" of machines, converting energy into mechanical motion to perform a wide range of tasks. From simple on-off switches to complex robotic systems, actuators find application in numerous fields, offering enhanced functionality, convenience, and efficiency.

Actuators come in various forms, each tailored to meet specific requirements and tasks. Let's explore some of the different types of actuators and some typical applications they excel in:

-

Electric Linear Actuators: These actuators are widely used for precise linear motion control. They are found in applications such as:

- Home automation: Powering motorized window treatments, adjustable furniture, and automated door locks.

- Healthcare: Enabling adjustable beds, patient lifts, and medical equipment positioning.

- Industrial automation: Controlling conveyor systems, robotic arms, and material handling mechanisms.

-

Hydraulic Actuators: These actuators harness the power of pressurized fluids, typically oil or water, to generate force and motion. They are commonly found in applications such as:

- Aerospace: Powering flight control surfaces like ailerons, elevators, and landing gears.

- Heavy machinery: Operating excavators, loaders, and hydraulic presses.

- Automotive: Controlling braking systems, power steering, and convertible roofs.

-

Pneumatic Actuators: These actuators use compressed air or gas to generate mechanical motion. They are widely utilized in applications like:

- Robotics: Enabling gripping mechanisms, robotic arms, and automated assembly lines.

- HVAC systems: Controlling dampers, valves, and air compressors for efficient climate control.

- Medical devices: Facilitating prosthetic limbs, pneumatic pumps, and surgical instruments.

-

Piezoelectric Actuators: These actuators utilize the piezoelectric effect to generate motion through the deformation of certain materials. They find application in areas such as:

- Nano-positioning: Enabling ultra-precise movements in scanning probe microscopes and atomic force microscopes.

- Optics and photonics: Fine-tuning mirrors, lens positioning, and laser beam steering.

- Medical devices: Facilitating precision dosing, microsurgery, and minimally invasive procedures.

-

Rotary actuators play a significant role in various applications, providing rotational motion for a multitude of tasks. Here are some key applications where rotary actuators are commonly employed:

- Robotics: Rotary actuators are extensively used in robotic systems to enable precise and controlled rotational movement. They power robot joints, allowing for versatile and articulated motion, which is crucial for tasks ranging from industrial automation to assistive robotics in healthcare.

- Manufacturing and Industrial Automation: Rotary actuators find applications in manufacturing processes, such as assembly lines, material handling, and machining operations. They enable precise positioning, rotary indexing, and actuation of robotic tools or grippers.

- Valves and Dampers: Rotary actuators are integral to valve control systems, facilitating the opening and closing of valves in industrial processes, water treatment plants, and HVAC systems. They also play a role in controlling dampers in ventilation systems for efficient airflow management.

- Automotive Industry: Rotary actuators are utilized in various automotive systems, including throttle control, steering mechanisms, convertible roofs, and electronic stability control. They ensure smooth and accurate movement, enhancing vehicle performance and safety.

- Aerospace and Defense: Rotary actuators are crucial components in aerospace applications, such as flight control surfaces (ailerons, elevators, rudders), landing gears, and missile guidance systems. They provide precise and reliable control of these critical functions.

- Entertainment and Stage Equipment: Rotary actuators are commonly found in entertainment industry equipment, such as rotating stages, automated lighting systems, and moving set pieces. They enable dynamic and captivating performances by smoothly and precisely controlling the movement of these elements.

- Renewable Energy: Rotary actuators are employed in renewable energy systems like wind turbines and solar tracking systems. They enable the adjustment and positioning of rotor blades in wind turbines for optimal wind capture and track the sun's movement for maximum solar energy absorption.

- Medical Devices: Rotary actuators play a role in medical equipment, including surgical robots, diagnostic imaging systems, and prosthetic devices. They provide controlled rotational movement for precise procedures, imaging adjustments, and assistive mobility.

4. How to choose

Finding the Perfect Fit:

Selecting the right actuator depends on various factors related to your specific requirements. Considerations include the extent of movement needed in your system (linear or rotary), the required force, whether the force will be consistent throughout the actuator's stroke or only in one direction, the importance of speed, and the availability of input energy.

These questions may seem broad, but they are crucial factors that need to be addressed. At FIRGELLI, we specialize in Electric Linear Actuators and also offer some Rotary Actuators. We have developed tools to assist you in determining the appropriate actuator model for your application. The typical process involves the following steps:

Step 1. Assess the type of movement required:

Does your application need rotary or linear movement. if it needs linear movement then goto our Linear Actuator selector page. If you need Rotary movement then goto our rotary actuators page.

Step 2 : Find out how much force you need:

The primary purpose of an actuator is to generate movement or lift an object. In your specific situation or application, it is crucial to determine the weight of the object. Keep in mind that the load distribution may not be uniform throughout the actuator's travel.

The load capacity of an actuator indicates the maximum weight it can lift. While different actuators may appear similar, their load capacities can vary. Therefore, before purchasing an actuator, it is essential to ensure that its capacity matches the weight of your object.

For instance, let's consider that you need to lift a weight of 100 lbs. In this case, we do not recommend buying a 100 lbs force actuator because it is important to have a safety margin built into the system. Running an actuator at its maximum power level is not ideal, just like driving a car at its maximum speed constantly. The car is not designed for this sustained high-speed operation.

Therefore, if you require a 100 lbs force, we would suggest choosing a 150 lbs or 200 lbs force model to ensure safety and optimal performance.

Step 3: Assess the precision level required:

When it comes to electric linear actuators, there are primarily two main types: those with feedback and those without. An actuator without feedback operates by simply moving in and out, without any built-in capability to determine its own position when it is between strokes. Unless you provide a signal to stop its movement during the stroke, it will continue to move.

However, certain applications require knowledge of the actuator's position during its stroke. There can be various reasons for this, such as the need to move something to a specific position or synchronize multiple actuators to run at precisely the same speed and timing, regardless of the force or changes involved.

In the latter case, a feedback actuator is necessary. These types of actuators include built-in sensors, such as Hall or Optical sensors, which provide feedback to a controller. This feedback allows the controller to constantly monitor and determine the actuator's position.

The FIRGELLI FCB-1 controller is a device that can be connected to up to four actuators simultaneously, reading the position signals from all four to provide synchronized control.

If positional control is not required for your application, a simple actuator without feedback will be more than sufficient.

Step 4: Consider the energy input:

If you are considering an electrical system for your actuator, it's essential to determine the available voltage and current draw. However, even if you opt for hydraulic or pneumatic systems, you will still require electricity to operate them. The key point here is that for mobile applications like cars or trucks, it's common to have a 12VDC power supply available.

5. How to install

Installing an actuator will depend on several factors, such as the location of the connecting points on the actuator. If you are installing a linear actuator, you must consider the type of motion it will produce. For instance, even though the actuator is linear, it doesn't mean that its motion will be strictly linear. Let's consider a scenario where you are lifting a hinged hatch to access the attic, similar to opening a trunk lid. In this case, the actuator will rotate through an angle as it opens the hatch or trunk lid. Therefore, it's crucial to allow the actuator to rotate freely during operation. This is why linear actuators are equipped with clevises on each end, which enable the use of a cross pin to connect the actuator to the application and allow for rotational movement. Typicall people use an Actuator bracket for each end of an actuator and these brackets are matched with the actuator model been used.

6. Versatility

"With the growing popularity of automation trends, customers are continuously seeking avenues to incorporate actuators into their applications."

Actuators offer a wide range of versatile features, making them suitable for numerous applications and industries. Their ability to generate precise and controlled movement enables their integration into diverse systems, enhancing automation and efficiency.

In industrial settings, actuators find utility in robotics, manufacturing equipment, and assembly lines. They enable precise positioning, lifting, pushing, or pulling of objects, contributing to streamlined production processes. Actuators are also commonly used in automotive applications, such as power windows, seat adjustments, and automated doors, providing convenience and comfort to users.

In the field of healthcare, actuators play a vital role in medical devices and equipment. They enable the precise movement of surgical tools, adjustable beds, and mobility aids, enhancing patient care and comfort. Actuators also find applications in the aerospace industry, where they control various functions such as landing gear deployment, wing flap adjustments, and satellite positioning systems.

Moreover, the versatility of actuators extends to home automation, where they are employed in smart home systems, motorized furniture, and automated window blinds. These actuators enhance convenience, energy efficiency, and overall comfort within residential spaces.

The adaptability of actuators is further evidenced by their use in agricultural machinery, ventilation systems, solar panels, and even artistic installations. They offer precise control, reliable operation, and endurance, allowing them to thrive in diverse environments and applications.

With their versatility and wide-ranging capabilities, actuators continue to revolutionize various industries, enabling automation, enhancing functionality, and improving overall performance in countless applications.

- Industry: industrial and agricultural vehicles, automated equipment, intralogistics transport equipment, window opening and ventilation systems...

- Medical: beds, tables, medical chairs and carts, patient lifts, mobility aids...

- Home furniture: armchairs, recliners, kitchen furniture, desks...

- Professional furniture: sit-stand desks, workstations, laboratory benches, control stations, display units...

Why choose FIRGELLI electric linear actuators? For more than 20 years, FIRGELLI has been supporting its customers in their product development projects with complete turnkey solutions.