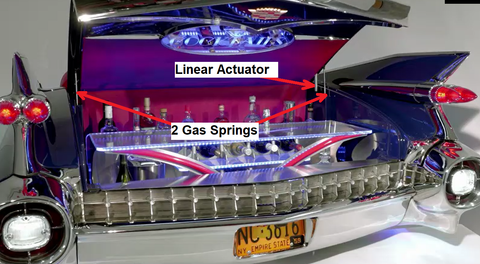

How to make a Linear Actuator driven Motorized pop-up cocktail cabinet that looks like a Cadillac?. Well here you can see the process that Jerome's Auto took to complete this very labor-intensive task to building the ultimate garage piece of furniture. He used 2 Linear Actuators to create the motion, one Actuator lifts the Trunk lid up which you will notice also has 2 gas springs on either side to help with the lifting and take the load away from the Actuator. Then once the first linear actuator reaches its full travel that signals the other Linear Actuator to push the liquor bar up into sight. All this was done with only 2 Actuators.

the basic principal is simple. One Actuator lifts the trunk lid open with a switch and an external limit siwtch (micro switch) is added to the system so that when the actuator is fully extended and the trunk lid therefore fully open the micro switch is triggered and then sends a signal to the relay to instruct the next actuator to start moving. The second Actuator then lifts the bar up into view where a longer stroke Linear Actuator is used to create the motion as a larger distance is required for the Bar pop-up.

The principal diagram above shows the entire system with the wiring diagram on the right hand side.

Gas springs are used on the trunk lid the same way they are used on many trunk lids already, they have the advantage of taking the weight for you so that manual opening is made simple and effortless. This also means the work that the Linear Actuator has to do is so much easier which will lengthen the life of the Actuator. Using gas springs to take most of the weight also has the advantage of allowing you to use a faster Actuator. You see Speed and Force always trade-off against each other in Linear Actuators, so a fast Actuator will have lower force than an Actuator that has low speed. This is just because of the gearing system that's inside the Actuators creating this trade-off. We have written a more details article just on the principals of Linear Actuators here.