What are the easiest drawer slides to install

Drawer slides can be as easy or as hard as you allow them, and it all depends on what type of slide you choose. In this guide we are going to cover the many different types of Drawer slides on the market, the many different ways a slide can be fitted into a cabinet, and then some help tips for you to decide which is the ideal type you need for your application. This is allot to cover especially when you consider that a drawer slide should be a very simple device to buy and install, but the reality is there are allot of external factors you must consider.

Different types of Drawer Slides

Drawer slides, or as they are sometimes called a drawer rollers, are a type of mechanism that allows smooth linear motion in one axis. They are most commonly used in pairs and found in a huge range of applications, mostly kitchen cabinets. Drawer slides generally work by having one component to slide over a slightly larger or smaller component of equal shape with roller bearings between them to create the smooth rolling function, which allows the entire mechanism to extend or retract. Drawer slides are not motorized but can be if a linear actuator is attached to provide the hands free motion for you. Generally, you will use drawer slides on their own and will likely encounter only two main types: Ball-Bearing Slides & Roller Slides.

1) Roller Slides

Roller slides consists of two components, the sliding main member strut and the fixed cabinet drawer strut. These types of slides are not fixed together until after you have attached them to both the drawer and the fixed cabinet. Only then can you slide the drawer into position and they then slide in and out freely.

Each strut having one wheel attached at each end is what allows the slides to run freely but it has its limitations. Having only onw wheel to carry the load is a huge disadvantage. This means that the load carried by the entire drawer and its contents is all focused onto the one wheel at either side of the cabinet drawer. This point load can be large for cabinets that need to carry more load and will eventually result in failure. Another thing to note is that the plastic wheels are not mounted onto bearings, they are simply plastic wheels on a metal axel that will eventually cause noise or wear problems at some point during its lifetime. One main advantage of these is that they are very cheap to purchase from any hardware store.

2) Ball-Bearing Slides

Ball-bearing slides as you can see from the image above are completely different to Roller slides. These make use of ball bearings encased in a bearing cage so they don't fall out, and some models offer a telescopic motion. By telescopic we mean that the Rails have 3 or more members that once combined together are able to extend the same distance or more than their total closed length. This great use of space is what gives them such a great appeal because the drawers are then able to slide out 100% of the drawers depth in a cabinet, where-as using a roller slide you can typically only achieve around 75% opening.

These types of slide rails offer extreme rigidity of the draw when fully opened or closed and allows them to carry a significant amount of weight. Plus the are easy to install as they have many hole patterns pre drilled along the length of each member for attaching them to both the fixed cabinet and the cabinet drawer. To open the the slides so that they can be installed simply press the lever down to unlock the full extended opening. Please view the video further down this article to see how to do that. Please note however not all Drawer slides come with the lever feature to take apart the drawer slides, all FIRGELLI drawer slides do have this feature however.

Ball-bearing drawer slides provide a huge durability life span and have much larger load rating compared to roller slides. Within our range of Ball Bearing slides we do even offer a very heavy duty type. Click here to view them. Heavy duty versions of ball-bearing slides

What are Slide Rails?

Slide rails, that can also called "linear guides", are another type of linear sliding mechanism that allow for very smooth linear motion. They consist of two basic components, a sliding carriage and a rail portion in which the carriage slides along. These carriages have there own bearing feature that carry all the weight and offering the smooth sliding. The rails that they run along can be in any length you want and you can cut them to any size you need where as with ball bearing drawer slides you cannot modify the rails so you have to chose the size that is closest to your needs. Also with Slide rails you can adjust the friction or stiffness of the carriage to make it easier or harder for it to slide up and down. Slide rails are commonly used in industrial & robotic applications, however they are now becoming popular in hidden sliding door applications in homes such as a hidden book case door or hidden wall panels for secret entrances because one of the great advantages of these slide rails is that you can add as many Carriages to the rail as you like to not only distribute the load but also make the sliding device more stable.

Both slide rails and drawer slides allow for linear motion, there is a main difference between them functionally, and that is the drawer slides are usually telescopic and more suitable to drawer applications, and slide rails are not telescopic but can be far more flexible for non drawer situations like hidden doors or sliding bookcases etc. . Practically, this means your drawer slides will collapse inwards, while slide rails will have a fixed length. There are also other differences, like thickness of the mechanism and load rating, that you’ll need to consider when choosing between the two mechanisms.

Things to consider

Here are a few things to consider when selecting the right type of sliding technology depending on your application.

1) Load Required

The load rating is the maximum allowable load the drawer slides or slide rail or whatever other mechanism you wish to use can handle. This would seem straightforward, just ensure you don’t go over your limit, right?. The load carried by your drawer slides will cause a shear stress on the mounting fasteners to which you screwed the slides into your cabinet with, for your drawer slides, and cause a corresponding force on your cabinet member. If these components cannot hold 400lbs, your design won’t either. To avoid any unexpected problems, you should determine the load capacity for your entire design.

Shear Stress on a Bolt[1]

2) Maximum Extension length

You are going to have an idea of how far you’d like your drawer slides to extend to. So, you’ll need drawer slides with a max extension as long as your requirement. This will also determinate the total length and fully retracted length of your drawer slides. Generally speaking, your max extension will be equal to your fully retracted length and half of your total length. Your cabinet component and your drawer component will also need to be as long as your fully retracted length to ensure safe mounting of the drawer slide.

Simple Technical Drawing of a Ball-Bearing Drawer Slide

3) Thickness of the material

The thickness of the drawer slide material is another consideration and is generally where a cheap Chinese knock-off would let you down the most. The thicker the material wall thickness the stronger the slides will be. cheap chinese drawer slides will simply feel tinny and will let you down once you start using them.

4) Mounting type

In most cases you will mount each drawer slide on opposites sides of each other, although, there are some that can be mounted on the bottom side of your drawer component or require only one draw slide, you should always follow what the manufacturer recommends. We discuss the different mounting styles further in this article as its very important.

Drawer Slides Installation options

Usually you wont have much choice on where to install the slide because the cabinet will dictate that for you, however in the event that you are designing this thing from scratch and do have the option of one or the other, it may help to know what your options are.

Mounting Types

Deciding the mount type is important but more than likely it has already been decided for you by the cabinet design. There are three mount types: side mount, center mount, and undermount. When determining the most suitable mount type, you have to consider the space between the cabinet opening and the drawer box.

Side-Mount installation method

Side mounting drawer slides or roller slides are the most common way to mount slides in a Drawer. As they come in pairs it makes it obvious this is the ideal place to mound them and also its a space saving method too. In both cases the rails are attached on the lower edge of the drawers so that they carry the weight in a compression loading way.

Telescopic extension slides offer any extension length in many different lengths from 10" to 60" extension. Our heavy duty drawer slides can carry up to 500 lbs of weight with extensions up to a whopping 60 inches.

Installation of both these types of drawer slides is pretty simple and can be done by anyone with a tape measure, screw driver and wood screws.

Center Mount installation method

Center mount drawer slides are sold individually as they mount under the drawer in the center and lay flat which is not very common in the industry. Its downside of this is that the drawer slide mechanism looses at least 80% of its weight capacity limit when turned horizontally in this orientation.

There is a benefit though, you only need one per drawer and the rail is completly hidden out of sight. This method is ideal if you want to keep the slides hidden and have a low weight capacity. The required clearance will be determined by the slide’s thickness.

Undermount Drawer slides

This undermount method takes space available at the sides of the drawer and moves it to under the drawers where these rails are attached. They carry the full weight of a compressive load manner but don't carry much load because these undermount drawer slides are not a telescopic type and they don't always open their full length of the drawer.

How to install Drawer Slides

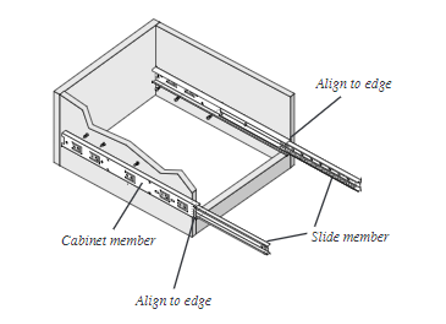

Step 1: Separate Cabinet and Drawer Members

This is called step 0 because it is not required or possible depending on the type and style of your drawer slides. All drawer slides will consist of at least two components, the cabinet member and the drawer member. As their names suggest, cabinet members mount to a stable or grounded component, i.e. the cabinet, and the drawer member attaches to the moving component, i.e. the drawer. For roller slides, the two members will most likely be separate when you purchase them. If not, you simply slide the drawer member forward until fully extended and pop the drawer roller over the roller of the cabinet member. For ball-bearing slides, they will have a third intermediate (slide) member that will stay connect to the cabinet member. If there is a release lever, like shown below, between intermediate member and the drawer member, they can be separated by pushing the lever and pulling forward. If the release lever is the on the right-hand side of the cabinet, you will need to push downwards to release, if on the left-hand side, you will need to push upwards to release. Not all ball-bearing slides will have release levers and if not, they cannot be separated.

It is important to separate the cabinet member and the drawer member, if possible, as it will make the rest of the install easier.

Step 2: Install Cabinet Member

Regardless of the type and style of your drawer slide, you will want to install the cabinet member first. Depending on your mounting configuration, place and align the cabinet member inside your cabinet or stable component. You’ll need to ensure that your set of drawer slides are level and parallel by ensuring that the distance from the edge of the cabinet to the edge of the slide is the same for both drawer slides and by using a level.

If you are planning to have overlay drawer fronts, which are drawers with fronts that overlap the sides of the cabinet, you should align the front of the cabinet member with the front edge of the cabinet. If you want to insert drawer fronts, which are drawers that have their front insert inside of the cabinet, you should setback the front of the cabinet member by the thickness of the drawer front.

Once you have the cabinet member aligned with your cabinet, fasten it to the cabinet by using your fasteners of choice into the recommend holes of the cabinet member. Typically, you want to fasten your cabinet member using at least three holes/slots. If your cabinet member has at least two slotted holes for mounting, like below, there are used to allow for adjustment at the end of the install. For the cabinet, you will usually use the horizonal slots for depth adjustments. If you want to make use of these slots for adjustments later, only fasten the cabinet member using two fasteners at this point.

If you plan to use bolts to fastener your drawer slide, you will need to pre-drill your bolt holes. You can do this by aligning the cabinet member inside the cabinet, mark the where the mounting slots are, then drilling the holes using the proper size drill bit.

NOTE: If you are using either releasing or non-releasing ball-bearing slides, you will need to slide the intermediate member back and forward to expose the sections of cabinet member for mounting. Once mounted, the intermediate member should slide smoothly over the attached cabinet member.

Step 3: Install Drawer Member

To install the drawer member for a releasing ball-bearing slide and a roller slide, you simply align the front of the drawer member to the front of the drawer. Again, you will want to ensure that both drawer members are level and parallel, but also that they are properly aligned with your cabinet members to allow for the drawer to fit with your cabinet. Once aligned, fasten it to the cabinet using your fasteners of choice into the recommend slots. Just like the cabinet member, slotted holes are used to allow for adjustments at the end of the process. For the drawer member, you usually will use the vertical slots to allow for a height adjustment.

For non-releasing ball-bearing slides, it will be recommended to have a second pair of hands or a support in place to hold the drawer in place while you mount it to the drawer slides. As you cannot remove the drawer member, you’ll have to have the slide fully extended to mount the drawer to each slide. Once done, you can simply push your drawer closed.

Step 4: Insert Drawer & Adjustments

Once all members are attached, you can insert the drawer into the cabinet. For roller slides, you’ll need to roll the drawer roller over the cabinet roller to position the drawer in place. For releasing ball-bearing slides, simply insert the drawer member into the intermediate member and push close. The release lever will lock as the drawer closes.

If you used slotted mounting holes to begin with, you can now make adjustments to the position of the drawer slide if needed. Typically, the cabinet member will have horizontal slots to adjust the depth of the drawer, while the drawer member will have vertical slots to adjust the height of the draw slide.

Once all adjustments are made, you will now want to fasten each member using third mounting hole, if not done all ready. You may also want to replace some of your screws and nuts to locking ones to improve stability. It is recommended that when supporting heavy loads, at least two locking screws are used per member.

How to select the right Drawer slides for your application

Selecting the right drawer slides for your application can seem complicated. There are so many types available on the market, some very complicated to install and require a professional and others very simple and can be done by anyone. So how do you choose from all the options?

There are three basic things you need to consider when choosing the ideal drawer slides.

- Drawer slide travel or extension: This refers to how far open you want the drawer to fully extend.

- Weight capacity: Most big box store style drawer slides are cheaply made and don't offer much in a way of weight capacity. To make things worse, when the drawer slides are fully extended that weight capacity decreases significantly, typically by 50%. It is important to determine if the weight capacity refers to when the drawer is closed or open. All Firgelli drawer slides weight capacities are rated for fully open. Hardware stores usually give this weight capacity when closed, so be careful.

- Mounting location: Side mounted drawer slides are the most popular and easiest to install. Center mount and undermount are also options.

What Length of Drawer Slides do you need?

Drawer slides generally come in extension lengths between 10 and 32 inches to fit a wide range of cabinetry requirements. We recommend you choose a slide length that corresponds to the size of your drawer, so you have to first measure your drawer depth. Once you know the length of extension required you also need to measure the closed length to make sure that whatever drawer slide length you buy will actually fit once closed without sticking out of the cabinet. For this reason you probably want to pick telescopic style drawer slides.

What are Telescopic Drawer Slides?

Telescopic drawer slides typically have three sections within each slide. This, for example, allows for a 20" extension even when the drawer slides are 20" in length when closed. If this was a two section drawer slides it would not be possible to extend 100% of its closed length, the maximum you could get would maybe be 15" but the weight capacity would be very low as a result.

Next, take into consideration the type of mount and measure out the slide length requirement accordingly. If you are going for side or side-under mount slides, you have to measure the distance from the inside face of the back of the cabinet to the front edge of the cabinet. Then, subtract approximately 1” from that for the required slide length.

In the case of center slides, just measure the length of the drawer, as the slide length has to be equal to that. However, be aware that there is a problem with this mounting style that we will go into in the next section.

It is very important to get the measurements correct. If your slides are shorter than the drawer length, they may not provide enough opening length or adequate support once fully opened. They might even cause the drawer to give out and fall off at some point.

How Strong of Drawer Slides do I Need?

The weight capacity determines the maximum load a drawer slide will be able to handle. Determining the typical holding capacity of the drawer and taking that into account is especially important if you are installing slides for heavy-duty use because most big box store type drawer slides don't offer weight capacities much over 50 lbs weight. All of Firgelli's drawer slides start at 400 lbs weight capacity.

Drawer slides are usually rated for 50 - 100 lbs and for household purposes slides with lower weight capacities are fine and will do the job nicely. Our specialty when it comes to drawer slides is for heavy duty and extra long stroke drawer slides.

These slides are the ball-bearing style, and they come in pairs but don't extend the full length that matches the closed length. They are mounted to the cabinet’s sides and are connected to locking devices that go on the underside of the drawer. They require less clearance, usually around 3/16″ to 1/4″ for each side and may be a little more work to install.

If you are looking for quality drawer slides with exceptional weight capacity and extension length, see the links below to Firgelli Autmations drawer slides.