Elon Musk's Tesla Bot Challenge: Can Advanced Robotics Outperform Human Flexibility with a Fraction of Actuators

The human body contains approximately 600 skeletal muscles, but the exact number can vary slightly from person to person. These muscles are responsible for a wide range of movements and play a crucial role in overall body function.

So how many actuators would a robot need to create the same level of flexibility and dexterity as a human?

In many robotic designs, a combination of fewer, more versatile actuators is used, along with sophisticated control algorithms, to achieve a wide range of motions and tasks. Moreover, some robotic systems use passive or compliant elements, like springs or flexible materials, to achieve more human-like behavior without increasing the number of actuators.

How many degrees of freedom does a human have

- Neck: 3 DOF (pitch, yaw, roll)

- Shoulders: 3 DOF per shoulder (6 in total)

- Elbows: 1 DOF per elbow (2 in total)

- Wrists: 2 DOF per wrist (4 in total)

- Fingers: 14 DOF per hand (28 in total, assuming 4 DOF for the thumb and 3 DOF for each of the other four fingers)

- Spine: Various estimates between 12 and 24 DOF (depending on the level of granularity)

- Hips: 3 DOF per hip (6 in total)

- Knees: 1 DOF per knee (2 in total)

- Ankles: 2 DOF per ankle (4 in total)

- Toes: 9 DOF per foot (18 in total, assuming 5 DOF for the big toe and 1 DOF for each of the other four toes)

Adding these DOF together results in an approximate range of 83 to 95 DOF. Keep in mind that this is a simplified representation and does not account for every possible joint movement or additional DOF that might be present in the human body. The actual number could be higher, particularly when considering finer details and smaller joints.

How many actuators would a robot need to create a similar level of degrees of freedom

How could differential mechanisms be used to cut down on the amount of actuators a robot could require

- Shared actuation: By connecting multiple joints or DOF to a single actuator using gears, linkages, or belts, the same actuator can control the motion of more than one joint. This reduces the number of actuators needed while maintaining the desired range of motion.

- Redundancy elimination: In some robotic designs, there may be redundant DOF that can be controlled by a single actuator without significantly impacting the robot's performance. Differential mechanisms can be used to couple these redundant DOF, allowing for more efficient use of actuators.

- Passive compliance: Differential mechanisms can be combined with passive compliant elements, such as springs or flexible materials, to enable a robot to adapt to external forces or changes in the environment. This can help reduce the number of active actuators needed while still providing the robot with the ability to perform complex tasks.

- Simplified control: Differential mechanisms can simplify the control of a robot by reducing the number of actuators and thus the number of variables that need to be controlled. This can lead to more efficient and easier-to-implement control algorithms.

Overall, the use of differential mechanisms in robotic designs can help reduce the number of actuators required, potentially resulting in a more cost-effective, lightweight, and energy-efficient system. However, implementing differential mechanisms also introduces its own set of challenges, such as increased mechanical complexity and potential loss of independent control over individual joints or DOF.

An example of a Differential mechanism

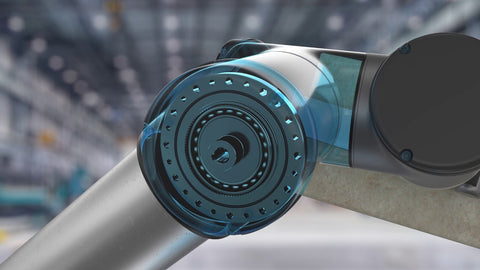

An example of a differential mechanism that can be used in robots is the Harmonic Drive. A Harmonic Drive is a type of gear arrangement that uses a flexible spline to achieve a high gear reduction ratio with minimal backlash and high precision.

In a robotic application, a Harmonic Drive can be used to control multiple joints or degrees of freedom (DOF) with a single actuator. The input of the Harmonic Drive is connected to the motor shaft, and the output is connected to the robot's joints. The flexible spline allows for precise motion control and smooth transmission of torque.

By using a Harmonic Drive in a robot, you can reduce the number of actuators required while still maintaining a high level of functionality and flexibility. The differential mechanism enables the robot to perform complex tasks that require multiple degrees of freedom with fewer actuators, reducing the robot's overall weight and complexity.

Overall, Harmonic Drives and other types of differential mechanisms offer significant benefits for robotic designs, allowing for more efficient use of actuators and reduced mechanical complexity while maintaining or even improving the robot's functionality and flexibility.

What is a Harmonic drive

A Harmonic Drive is a type of high-precision gear arrangement used in mechanical systems, including robots. It consists of three main components: a circular spline, a flex spline, and a wave generator. The flex spline is sandwiched between the circular spline and the wave generator and is connected to the output shaft of the gear system.

The wave generator is connected to a motor or other power source and is used to create a wave motion in the flex spline. As the wave generator rotates, the wave motion is transmitted to the flex spline, which then causes it to rotate and mesh with the circular spline. The resulting motion of the flex spline is transmitted to the output shaft.

The key advantage of a Harmonic Drive is its high gear reduction ratio, typically in the range of 50:1 to 100:1, with minimal backlash and high precision. This allows for precise motion control and torque transmission, making it ideal for robotic applications that require accurate control of multiple joints or degrees of freedom.

Harmonic Drives are widely used in robotic designs, especially for small-scale robots, where they can reduce the number of actuators required while still maintaining a high level of functionality and flexibility. They are also used in other precision machinery applications, such as aerospace, medical equipment, and factory automation.

What are the trade-offs when using differential mechanisms in a robot

- Mechanical complexity: Differential mechanisms often involve additional gears, linkages, or belts, which can increase the complexity of the robot's mechanical design. This can lead to challenges in fabrication, assembly, and maintenance.

- Reduced independent control: By coupling multiple joints or degrees of freedom (DOF) to a single actuator, you may lose some independent control over individual joints or DOF. This can make it more challenging to perform certain tasks or achieve specific configurations, as the motion of one joint might influence the motion of another.

- Potential backlash and friction: The additional mechanical components used in differential mechanisms can introduce backlash and friction, which may affect the robot's precision, response time, and efficiency. This can be particularly important for tasks that require high accuracy or fast, dynamic motions.

- Control complexity: While the overall number of actuators and control variables might be reduced, the coupling of multiple joints or DOF can lead to more complex relationships between the inputs and outputs of the system. This can make it more challenging to develop and implement effective control algorithms.

- Load and torque distribution: Differential mechanisms may affect the distribution of loads and torques across the robot's structure, which can influence the overall performance and durability of the system. Depending on the design, this may require additional reinforcements or careful consideration of the materials used.

- Compromised redundancy: In some cases, using differential mechanisms to eliminate redundancy might result in a less robust system, as the failure of a single actuator could affect multiple joints or DOF.

When deciding whether to use differential mechanisms in a robot, it's essential to weigh these trade-offs against the potential benefits, such as reduced actuator count, lower cost, and decreased weight. The choice will ultimately depend on the specific goals and requirements of the robotic system being designed.

If the new Tesla bot is only going to have 28 actuators, how will it compare to a human

Human flexibility:

- Degrees of freedom (DOF): Approximately 83 to 95 (considering major joints)

- Actuators: Around 600 muscles

- Degrees of freedom (DOF): Not specified

- Actuators: 28

From this comparison, it's clear that the Tesla Bot will have significantly fewer actuators than a human. This suggests that the Tesla Bot's flexibility and dexterity may not fully match that of a human, at least in terms of independent control of joints and degrees of freedom. However, it's essential to note that flexibility and dexterity are also highly dependent on the robot's design, control algorithms, and the use of mechanisms like differentials or compliant components.

Some examples of what the Tesla-Bot could be capable of achieving, even with only 28 actuators

The Tesla Bot is still in development, and the specific applications and tasks it will be able to accomplish with its very limited use of actuators are not yet fully defined. However, based on the announced specifications and general capabilities of humanoid robots there are still a few jobs this Robot could be able to do. A few examples include:

- Manufacturing: The Tesla Bot could be used in manufacturing processes, such as assembling small parts or packaging goods. Its dexterity and precision could make it well-suited for tasks that require delicate handling of materials.

- Household tasks: The Tesla Bot could assist with household chores, such as cleaning, cooking, and laundry. Its ability to move and manipulate objects could make it useful for tasks that require physical dexterity and mobility.

- Healthcare: The Tesla Bot could assist in healthcare settings, such as providing assistance to patients with limited mobility or helping with tasks in a medical laboratory.

- Construction: The Tesla Bot could potentially be used in construction tasks, such as heavy lifting or moving materials. Its strength and ability to manipulate objects could make it well-suited for tasks that require physical power and endurance.

- Education: The Tesla Bot could potentially be used in educational settings, such as teaching students about robotics or assisting with hands-on learning activities.

It's important to note that the specific applications and tasks the Tesla Bot will be able to accomplish will depend on its final design, control algorithms, and intended use. The above examples are only a few potential applications, and the capabilities of the robot could be much broader.

Author: Robbie Dickson

Wikipedia: Robbie Dickson