What is a Linear Actuator? The Ultimate Guide to Understanding Linear Actuators

If you’ve ever asked, "What is a linear actuator?" you’ve landed on the perfect page. This comprehensive guide from Firgelli Automations provides everything you need to know about actuators, with a deep dive into electric linear actuators. Whether you're a beginner or an engineer, this article will equip you with the knowledge to understand how they work, their applications, and how to choose the right linear actuator for your needs.

What is a Linear Actuator? A Simple Definition

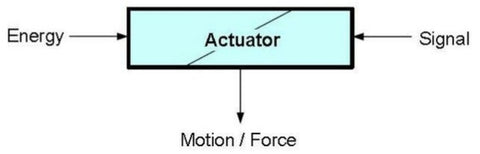

A linear actuator is a mechanical device that converts energy—typically from an electric motor—into controlled, straight-line motion, known as linear motion. Unlike rotary actuators that produce circular motion, linear actuators move objects forward and backward (push and pull) along a single axis. At its core, an electric linear actuator uses a motor (AC or DC), gears, and a lead screw to create this precise linear movement. For a broader overview of actuators, including rotary types, check out our detailed guide: "Actuators."

Choosing the right linear actuator can be tricky, so we’ve also created a must-read article: “Don’t Buy a Linear Actuator Until You Read These Five Steps.” It’s packed with tips to avoid common mistakes when purchasing online.

Need help sizing an actuator for your project? Use our Linear Actuator Calculator. Simply input your project details, and it will recommend the ideal specifications for your application.

Video Demonstration of an Actuator

How Does a Linear Actuator Work?

An electric linear actuator transforms the rotational motion of an electric motor into linear motion. Here’s the basic process: an AC or DC motor spins a series of gears, which drive a lead screw. A nut attached to the lead screw moves along its threads, pushing or pulling a rod to create linear motion. This mechanism allows linear actuators to lift, lower, slide, tilt, or adjust objects effortlessly with the press of a button.

Linear actuators are versatile, powering everything from industrial machinery to home automation projects. They excel in the "3 Ds"—Dirty, Dull, or Dangerous tasks—while also enhancing modern living with applications like TV lifts, adjustable desks, and kitchen appliance automation. With easy installation, energy efficiency, and minimal maintenance, electric linear actuators outperform hydraulic and pneumatic alternatives by eliminating the need for pumps, hoses, or complex setups.

What is a Lifting Column?

A lifting column is a type of linear actuator designed for extended stroke lengths. Featuring multiple telescoping stages, lifting columns can extend significantly further than standard actuators while collapsing into a compact form. They also include built-in linear guides, making them ideal for applications requiring stability under side loads, unlike traditional linear actuators.

What is a Micro Linear Actuator?

Micro linear actuators are compact versions of linear actuators, tailored for small-scale applications or tight spaces. With strokes typically ranging from 10mm to 100mm, they’re perfect for precise, low-force tasks. However, their smaller motors limit their force output compared to standard models.

The Benefits of Electric Linear Actuators Over Hydraulic Systems

Electric linear actuators offer unmatched simplicity, safety, and precision compared to hydraulic systems. They deliver smooth motion control for lifting, tilting, or pushing with high forces, all without the mess of hydraulic fluid. Hydraulic actuators, while powerful, require pumps, valves, and piping—making them bulky and expensive. Electric actuators, driven by a motor and lead screw, are compact, cost-effective, and provide superior control, longevity, and eco-friendliness.

Real-World Applications of Linear Actuators

Watch this video to see how linear actuators enhance everyday life:

Linear actuators are everywhere, automating tasks in homes, industries, and beyond. Examples include:

- Motorized hatches

- Kitchen appliance lifts

- Throttle control

- Marine engine hatches

- Slide-out steps

- Snowplow adjusters

- Hoppers

- Hidden doors

- Solar panels

- Sliding doors

- Sliding window treatments

- Farming implements

- Animatronics and robotics

Industrial uses include damper control, height-adjustable workstations, and home automation like TV and projector lifts.

What is the Difference Between Static Load and Dynamic Load?

Dynamic load refers to the force a linear actuator applies while moving, while static load is the force it can hold when stationary. Understanding both is key to selecting the right actuator for your project.

In What Direction Can Loads be Applied to Linear Actuators?

Linear actuators handle tension (pulling) and compression (pushing) loads effectively. However, side loading—force applied perpendicular to the actuator’s axis—should be avoided. For side-loaded applications, pair actuators with drawer slides or use a track actuator to manage the load.

Is Side Loading Permissible on Linear Actuators?

Sideloading, or radial loading, is a force applied perpendicular to the linear actuator centerline. Eccentric loading is any force whose center of gravity does not act through the longitudinal axis of the actuator. Both sideloading and eccentric loading should always be avoided as they can cause binding and shorten the life of the linear actuator. However, if you use a drawer slide in the application this will greatly impact how much loading can be applied. By placing the object you are moving on a drawer slide it allows the weight to be carried by the slide instead of the actuator taking all the weight. Another option when you are dealing with side loading is to use a track actuator.

Do Linear Actuators Have Limit Switches?

Most linear actuators feature built-in limit switches (e.g., electro-mechanical or magnetic) to stop motion at full extension or retraction, preventing motor burnout. Adjustable limit switch actuators, like Firgelli’s patented model, allow users to fine-tune stroke endpoints. Learn more in our article: "How Does an Adjustable Limit Switch Actuator Work?"

What Type of Motors do the Linear Actuators Use?

Linear actuators use AC (220-240 VAC) or DC (12V or 24V) motors. DC motors, especially 12V, are most common for their efficiency in compact, high-force applications.

Are Linear Actuators Available in Different Speeds?

Check out this video on our Premium Linear Actuators:

Speed varies by gearing—faster speeds reduce force, and vice versa. Each actuator model lists available speed options.

What is the Duty Cycle Capability of a Linear Actuator?

Duty cycle measures an actuator’s “on-time” as a percentage or distance traveled over time. Learn more in our blog: "What is Duty Cycle in a Linear Actuator?"

What Type of Mounting do the Linear Actuators Have?

Actuators typically feature clevis mounts for pivoting, with custom brackets available.

What Type of Enclosures do the Linear Actuators Have?

Actuators typically feature clevis mounts for pivoting, with custom brackets available. IP ratings (e.g., IP54 for dust, IP66 for waterproofing) indicate protection levels. See our IP ratings guide.

Is Back-driving Possible in Electro-mechanical Linear Actuators?

Most actuators can back-drive under excessive force unless equipped with a brake.

Can a Linear Actuator be Run Into a Hard Stop?

Avoid hard stops, as they can jam the actuator and damage it.

What Are the Common Factors in the Failure of a Linear Actuator?

Overloading, improper mounting, or extreme conditions can shorten actuator life. Our actuator replacement guide helps with future repairs.

Can Two or More Linear Actuators be Synchronized?

For synchronized motion, use feedback actuators (e.g., with potentiometers) and a controller. Details in our blog: "Achieving Synchronized Motion."

Are the Actuators Lubricated for Life?

Actuators are grease-lubricated for life and tested to operate from -20°C to +100°C, ensuring durability.

Temperature Test

In the temperature test, the actuators are tested to operate in extreme temperatures as well as to endure rapid changes in temperature. In most cases, tests are performed on the actuator to withstand going from a +100°C environment to -20°C repeatedly and still maintain full functionality.

Future Innovations in Linear Actuators

Emerging features include smart sensors, AI-driven controls, wireless connectivity, energy harvesting, self-diagnostics, and noise reduction—enhancing performance and sustainability.

For a technical breakdown, read "Inside a Linear Actuator."