DC Gear Motors: Unraveling Precision Motion and Versatile Applications

In the ever-evolving landscape of mechanical engineering, DC gear motors have become an indispensable force, revolutionizing various industries. Combining the remarkable power of DC motors with the mechanical advantage of gearboxes, these motors excel at delivering high torque at low speeds, making them versatile and ideal for numerous applications. This comprehensive blog post aims to provide an in-depth exploration of DC gear motors, covering their fundamental principles, manufacturing process, diverse applications, control mechanisms, and a guide to selecting the best motor for specific needs. Additionally, we'll delve into their pivotal roles in automotive technology, RV applications, robotics, and home automation.

Understanding DC Gear Motors

DC gear motors represent a brilliant amalgamation of two critical components: a DC motor and a gearbox. The DC motor serves as the primary workhorse, converting electrical energy into mechanical rotary motion through the interaction of magnetic fields. On the other hand, the gearbox, often referred to as a reduction gear, is responsible for transforming the high-speed output of the DC motor into lower speeds while substantially increasing torque. This process is achieved by employing gears with varying numbers of teeth, enabling precise speed reduction and a remarkable boost in mechanical advantage.

Understanding Gear Ratio's in detail

This reduction in speed and increase in Torque are usually referred to as the "Gear Ratio" to complete the process. Typically the higher the gear ratio the higher the output torque and lower speed, conversely, the lower the gear ratio, the higher the speed and lower the force. For example, lets say a gear motor has a gear ratio of 10:1 (we would say 10 to 1 gear ratio) then this means the output speed of the DC motor rotates 10 times to get one revolution of the shaft coming out of the gear box. THUS, increase the torque approximately 10 fold, but reducing the speed 10 fold too.

Gear Ratio losses due to efficiency

In theory, a gear ratio of 10:1 would result in the torque increasing by 10 times and the speed decreasing by 10 times. However, in real-world applications, there are some losses in the system that can affect the actual output.

Gear systems are not 100% efficient, and there are mechanical losses, such as friction, which can lead to a reduction in the overall efficiency of the gear motor. These losses can slightly decrease the output torque and speed compared to the ideal theoretical values.

The efficiency of a gear system is typically expressed as a percentage and varies depending on the quality of the gears, lubrication, and other factors. For example, if the gear system has an efficiency of 90%, the actual torque increase and speed decrease would be slightly less than the theoretical 10 times.

So, while the gear ratio of 10:1 does indicate a considerable increase in torque and decrease in speed, it's essential to consider the efficiency of the gear system to determine the exact output values in real-world applications.

How a DC gear motor can also function as a rotary actuator

In addition to their primary role as powerhouses for mechanical motion, DC gear motors can effectively double as rotary actuators in certain applications. A rotary actuator is a type of motor that converts electrical energy into rotational motion, precisely controlling the angular position of an output shaft. With the integration of a gearbox, DC gear motors inherently possess the ability to perform rotary actuation, making them even more versatile. By leveraging the gear reduction capabilities of the gearbox, the output shaft's rotational speed and position can be controlled with remarkable precision. This unique characteristic allows DC gear motors to excel in applications that require precise angle adjustments and controlled rotational movements. As a result, they find extensive use in various industrial processes, robotics, and automation systems where accurate and repeatable rotary motion is paramount.

If DC gear motors are not suitable as rotary actuators due to specific limitations or constraints, it is important to consider other types of motors that specialize in rotary actuation, such as stepper motors or servo motors. Stepper motors provide precise incremental movement in discrete steps, while servo motors offer closed-loop control for accurate and continuous rotation. Understanding the distinctions between these motor types ensures the optimal selection for applications where precise rotary motion is essential.

The Manufacturing Process of DC Gear Motors

The manufacturing process of DC gear motors is an intricate dance of precision engineering and cutting-edge technology. It commences with the fabrication of the core components of the DC motor, including the rotor, stator, and commutator. The rotor consists of windings that create magnetic fields when energized, interacting with the stationary magnetic fields generated by the stator to induce rotation. The commutator plays a vital role in converting direct current into alternating current, ensuring the continuous rotation of the rotor.

Simultaneously, the gearbox components, such as gears and shafts, undergo meticulous manufacturing to guarantee smooth operation and minimal mechanical losses. Gears are typically constructed from steel or plastic, depending on the application's requirements. The tooth profiles and surface finishes of these gears are carefully crafted to minimize friction and ensure efficient power transmission. Once the DC motor and gearbox components are ready, they are assembled with precision, ensuring seamless integration. The entire motor is then lubricated, and a series of rigorous tests are conducted to assess its quality and performance, guaranteeing a reliable end product.

Applications of DC Gear Motors

The remarkable efficiency, compact size, and versatility of DC gear motors make them suitable for a wide array of applications, including but not limited to:

a. Automotive: One of the most ubiquitous applications of DC gear motors in the automotive industry lies in windshield wiper systems. The high torque and slow speed capabilities of these motors allow wiper blades to glide across windshields effectively, enhancing visibility during adverse weather conditions. Additionally, DC gear motors find application in power windows, mirror adjustment, seat adjustment systems, and even in power steering systems.

b. RV Applications: In the realm of recreational vehicles (RVs), DC gear motors play a pivotal role in powering slide-out mechanisms, leveling systems, and awning controls. Their ability to provide precise control and ample torque ensures the smooth operation of various RV components, significantly enhancing the overall camping experience for enthusiasts.

c. Robotics: The realm of robotics benefits greatly from the attributes of DC gear motors. Their compact design and impressive torque capabilities make them an ideal choice for actuating robot joints, wheels, and arms. The gear reduction ensures precise movement and control, allowing robots to execute intricate tasks with unparalleled accuracy and dexterity.

d. Home Automation: The charm of home automation lies in the seamless integration of various automated systems. DC gear motors find their niche in applications such as smart locks, curtain control systems, and automated blinds. Their quiet operation and energy efficiency contribute to the creation of a smart and harmonious home environment, accentuating the modern lifestyle.

Controlling the speed and direction of DC gear motors is of utmost importance to ensure their efficient operation in diverse applications. Several methods have been devised to achieve precise motor control:

a. Pulse Width Modulation (PWM): PWM stands as one of the most widely used techniques for controlling the speed of DC gear motors. By varying the duty cycle of the PWM signal, the average voltage applied to the motor can be adjusted, thereby regulating the motor's speed with utmost precision.

b. H-Bridge Circuit: The H-bridge circuit serves as a popular choice for achieving bidirectional control of the motor. By switching the direction of current flow through the motor using transistors, the motor can be made to rotate in either direction, allowing for complete control over its motion.

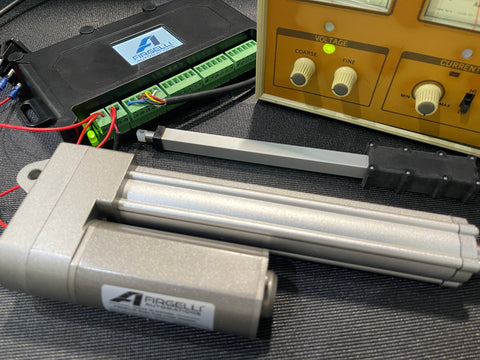

c. Motor Controllers: To simplify the process of controlling DC gear motors, dedicated motor controllers, such as motor driver ICs, are available. These controllers often come equipped with built-in protection features, ensuring the motor is shielded from potential damage due to overcurrent or other adverse conditions. For microcontroller-based projects, motor controllers facilitate seamless integration, promoting an optimal user experience.

Selecting the most appropriate DC gear motor for a specific application demands careful consideration of several factors:

a. Torque Requirements: Evaluating the required torque for a given application is paramount. Analyze factors such as load weight, friction, and other resistive forces to determine the appropriate torque rating needed for the motor.

b. Speed Requirements: Understanding the desired speed range for an application is crucial. Calculating the gear reduction ratio needed to achieve the desired speed can significantly impact the motor's overall performance and suitability for the task at hand.

c. Efficiency: Opting for a motor with high efficiency is essential to reduce energy consumption and heat generation. An efficient motor not only minimizes operational costs but also enhances overall performance and extends the motor's lifespan.

d. Size and Weight: Considering the available space and weight restrictions for the motor is vital. Compact and lightweight motors are preferred for applications with limited space, ensuring easy integration without compromising functionality.

e. Operating Environment: Evaluating the motor's ability to withstand the operating environment's challenges is critical. Selecting a motor with appropriate protection against dust, moisture, and temperature variations ensures optimal performance and longevity, even in harsh conditions.

f. Voltage and Current Ratings: Ensuring that the motor's voltage and current ratings align with the power source and control circuit is paramount. Adequate consideration should be given to avoid underpowering or overpowering the motor, as such mismatches can lead to reduced performance or even motor damage.

Conclusion

DC gear motors stand as a testament to the ingenuity and prowess of modern engineering. Their ability to combine the robust power of DC motors with the mechanical advantage of gearboxes has made them indispensable across various industries. Whether it's enhancing automotive safety with windshield wipers, powering smooth RV experiences with slide-out mechanisms, enabling the intricate movements of robotics, or adding finesse to home automation, DC gear motors continue to redefine precision motion.Understanding the manufacturing process, control mechanisms, and essential factors for selecting the most suitable motor for specific applications empowers engineers and hobbyists to unlock the full potential of DC gear motors. As technology progresses and innovation thrives, DC gear motors will undoubtedly continue to evolve, further enriching the world of mechanical engineering with their indomitable prowess.

Check out our Gear Motors here

Click here