Choosing the ideal Electric Linear Actuator for your application is not as simple as it sounds. You need to take into consideration, strokes, forces, leverage etc in order to get it right. Making the wrong choice could get very costly, so we made this article to give you a quick understanding on what you need to know.

Lets start with What an Electric Linear Actuator is. In basic terms a linear actuator is a device that produces motion in a straight line and is powered by an external energy source, in this case electricity. This motion is commonly achieved with a rod extending and retracting or with a slider that moves on a track.

Linear actuators have an almost limitless number of applications. They are used in the health care sector, in machine and industrial work applications, in home and office automation, in solar tracking systems, and even in aerospace technology. It is said that we use a Linear Actuator at least once a day in our every day lives, however we probably don't realize it. The following steps will help you in determining which linear actuator will suit your application.

Step 1: Determine the amount of force required

What is the weight of the object to be moved or lifted in your project? Firgelli Automation's carries a range of products from mini linear actuators with a force capacity of 15-lbs to industrial heavy duty linear actuators capable of moving forces up to 2,200 lbs.

Be warned however, just because that hatch your lifting only weighs 50lbs, how you lift it can multiply that number significantly. Take the picture above: this simple hatch may only weigh 50lbs but because the attaching point of the end of the actuator is close to the pivot point, the force required to lift this can easily become 500lbs force requirement. Use our force calculator (below) in situations like this to calculate the real force for you.

Step 2: Determine the distance the actuator needs to move

What is the distance that you want to move something in your project? This is called the stroke length in an actuator and it determines how far the linear actuator will move in one direction. We carry various linear actuators with strokes ranging from 1" up to 60" so you wont struggle to find the right Actuator to fulfill your needs

Step 3: Determine the speed required

Does your project need to move fast or slow? The speed of a linear actuator is measured in distance (inches) per second. Generally, the higher the force required the slower the actuator will move. its is worth remembering that Force and Speed trade-off against each other. There are ways to increase the speed in certain types of applications. For example, if you are opening and closing a hatch, you can speed up the opening and closing of that hatch by installing the Actuator close to the pivot point. However the closer to the pivot point you install the actuator the more force is required to open and close that hatch. This is the simple laws of physics, specifically leverage.

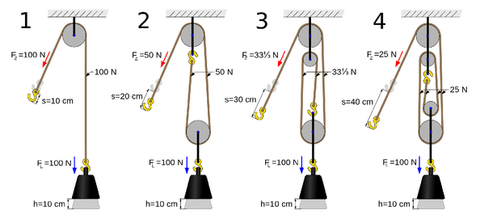

Pulleys are another way to increase speed of an application. By using pulleys with a certain ratio you can lift more force but the speed can be reduced.

Step 4: Based on your project choose a type of Linear Actuator

With the technical specifications of your project worked out you can see which linear actuators will work with your parameters. Different types of linear actuators are better suited to certain projects. Rod-style actuators are the most common and simply feature a shaft which extends and retracts. Track actuators are great for tight spaces where a sliding block is ideal due to its unchanging length whether extended or retracted. A column lift is ideal if you need an actuator with a long stroke in relation to its retracted size. And of course there are actuators to lift your TV or drop down your TV.

Now that you know the basics of linear actuators you will be able to choose one for your next project. To find the ideal Actuator just go to our Linear Actuators pages and pick based on force/speed/stroke. Using the search feature will also help get to where you need to be.

After selecting the right Linear Actuator for your application, you then need to decide how to control it. We have written several articles on how to control a Linear Actuator here.