The first thing to know is that linear actuators do exactly what its name implies: it actuates (or 'moves') in a linear (or 'straight') fashion. There are many different ways that an actuators electric motor can do this. For rod actuators, their linear motion is commonly achieved with a rod extending and retracting. For track actuators, this would be a slider that moves up and down on a track. It's motion is created by using a lead-screw. The screw turns either clockwise or counter-clockwise and this causes the shaft, which is basically a nut on the screw to move up and down the screw as the screw turns. This is what converts rotary motion from the electric motor to linear motion.

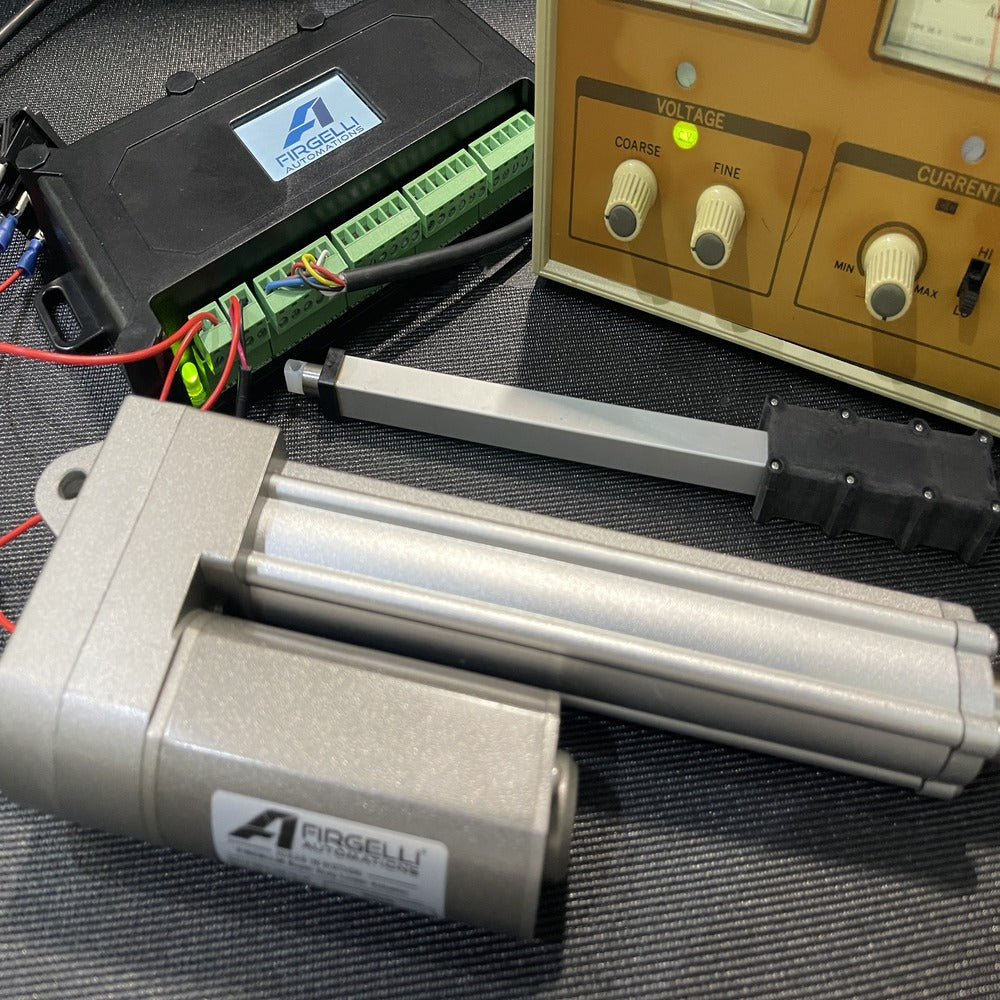

The electric motor used is either a AC or DC motor, most however run on a 12v DC electric motor. To make an electric actuator go in the opposite direction you simple reverse the wires from the linear actuator (reverse polarity) from the battery or power supply. This is typically done through a switch that automatically reverses the polarity of the electric motor for you. Different speeds and forces are achieved by using different gear ratio's inside the electric gearbox actuation system. Please remember in a electric actuator, force and speed trade off against each other. That means if you want high force you have to settle for a lower speed than if you require lower force. This is because the only constant in a electric actuator is the electric motor's speed and force for a given input voltage.

To make our linear actuator shaft stop when it gets to the end of the stroke, our products have built-in limit switches or micro switches as they are sometimes known. These limit switches are inside the main shaft and are nothing more than a small switch that is triggered by the nut inside that slides up and down the screw. There is one for the top extended position and one for the lower retracted position. For more information on this, check out our blogs page.

A FIRGELLI linear actuator offers simple maintenance free operation, that's easy to install and operate. But first what is a linear actuator? It is a device that requires an electrical energy input and an external an optional signal input. Its a device that converts the rotational motion of an AC or DC electric motor into linear motion. It can provide both push and pull movements. This movement makes it possible to lift, drop, slide, adjust, tilt, push, or pull objects with the simple push of a button. Today there are hundreds of millions of electric actuators used in the world to perform many different tasks. Actuators consists of a DC or AC electric motor, a series of gears, and a lead screw with a driving nut that pushes the main rod shaft in and out.

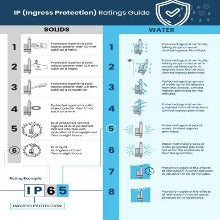

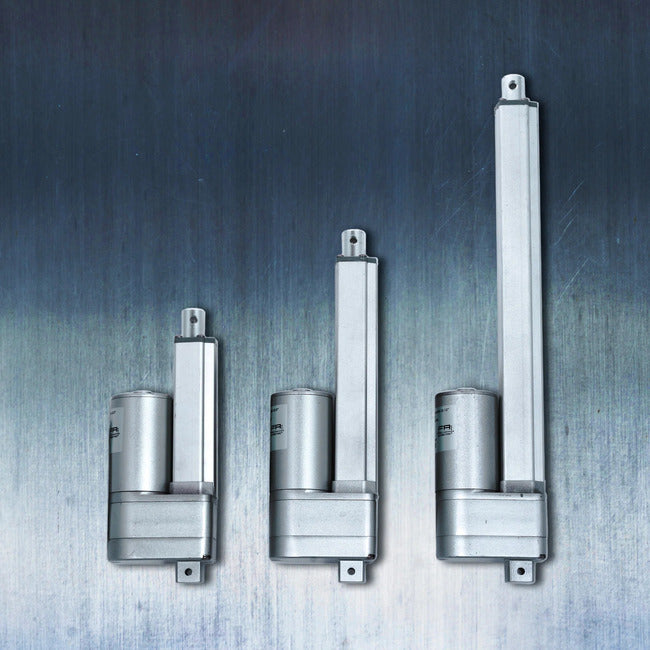

You have a few options for selecting the ideal linear actuator for your application. You can call us to get some help or you can use our actuator calculator, or you can browse through our many actuator products pages to get a feel for all the different types we have available to you. Typically when choosing the ideal linear actuator you start off with the force. This is the force you think you need to lift or move the object you require moving. As a rule of thumb, we always suggest to people to buy the electric actuator that offers double the force you think you need, thereby allowing for a 50% safety factor. From there you will also need to know the actuators stroke length. This is the length you need to move your object in and out. If the exact stroke length is not available then you can install an external limit switch to stop the electric actuator exactly where you want it to. We offer this kit also and the wiring diagram to go with it which is very easy to follow. You also need to think about the IP-Rating you need for your actuator of choice. This will depend on how harsh the conditions your actuator will operate in. For more on IP-Ratings check out our guide.

Actuators run at their max speed out of the box when no force is applied to them. An electric actuators speed depends on a few things like force, the gear ratio, and voltage. A 24vdc power supply will make a 12vdc electric actuator run twice as fast, meaning that speed is directly proportional to voltage input. If you want to slow down your actuator we offer 2 speed controller options for exactly that situation. The speed controller lets you set different speeds of the 12 volt actuator simply by adjusting the voltage automatically for you to slower down the actuator, however these cannot speed up the linear actuator faster than it can already go. For a simple single 24 volt actuator or 12 volt actuator speed controller try this Speed controller. For a much more advanced speed controller using a touchcreen, that can control the speed of up to 4 actuators, try our FCB-1 Controller.

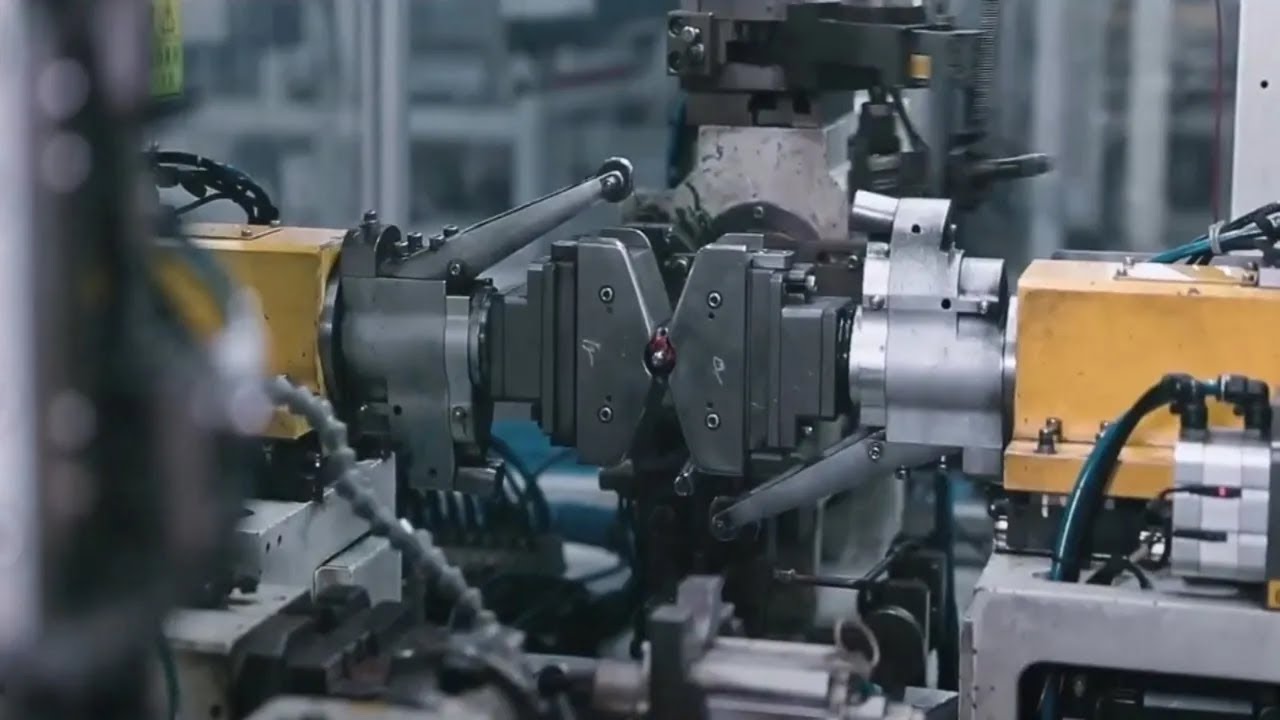

Linear motion refers to the straight-line movement of an object from one point to another, without deviation or rotation. It is characterized by uniform displacement over time, creating a predictable and consistent path. In the context of our electric actuators, linear motion is the controlled and precise movement along a linear path, enabling industry applications that require accurate positioning, pushing, pulling, or lifting.

Our electric actuators are engineered to provide smooth and reliable linear motion, making them essential components in various industries, including robotics, automation, and more. They enable machines to move with precision and efficiency, whether it's automating processes or creating fluid robotic motions. Our electric actuators embody the essence of linear motion, enhancing functionality and contributing to the advancement of industries that rely on accuracy and dependable movement.

Our website only shows what is in stock, those options that are out of stock are greyed out so that you know it is not available to purchase. So therefore only in-stock products can be purchased online. Drop us a line to enquire about when particular products will be returned.

Yes, a FIRGELLI actuator can replace your old actuator. FIRGELLI offers a wide range of electric linear actuators with various specifications, including stroke length, force capacity, and mounting options. Before making a replacement, it's essential to consider the following steps:

- Compatibility Check: Compare the specifications of your old actuator with the FIRGELLI actuator you're considering. Ensure that the stroke length, force capacity, and mounting dimensions match or closely align with your requirements.

- Mounting and Connections: Check whether the mounting brackets, attachment points, and connection interfaces of the FIRGELLI actuator are compatible with your existing setup.

- Power Supply: Confirm that the power requirements (voltage, current) of the FIRGELLI actuator match your power supply or system specifications.

- Control and Feedback: If your old actuator had specific control features or feedback mechanisms, verify that the FIRGELLI actuator provides similar functionalities or offers compatible control options.

- Integration: Consider any modifications needed to seamlessly integrate the FIRGELLI actuator into your application. This could include adjusting mounting points, making electrical connections, or programming control signals.

- Consultation: If you're uncertain about compatibility or installation, feel free to reach out to FIRGELLI's customer support. They can provide guidance and recommendations based on your specific situation.

For a more in depth guide on how to replace your old actuator, we have made a replacement actuator guide for you.

Yes we do. Our discount structure is based on volumes, so the more you buy the more you save its that simple. Simply give us a call to get volume discounted pricing, but these volumes start at 11pcs or more.